GCM

COMPLEX CUTTING MADE SIMPLE

COMPLEX CUTTING MADE SIMPLE

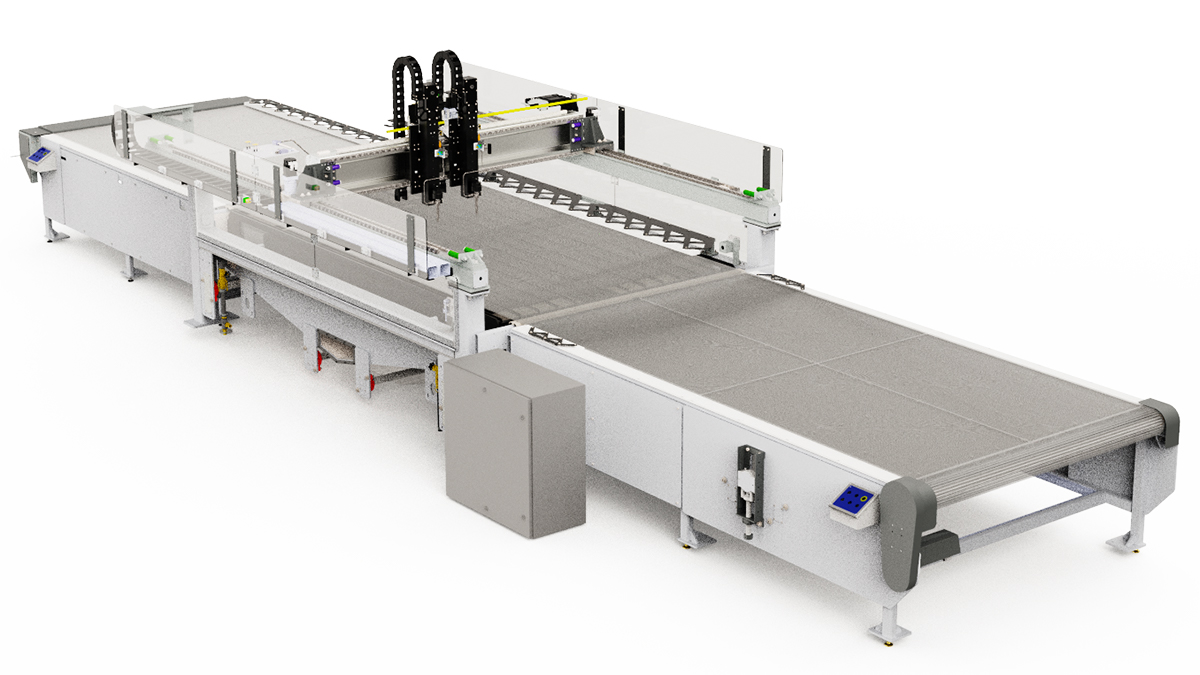

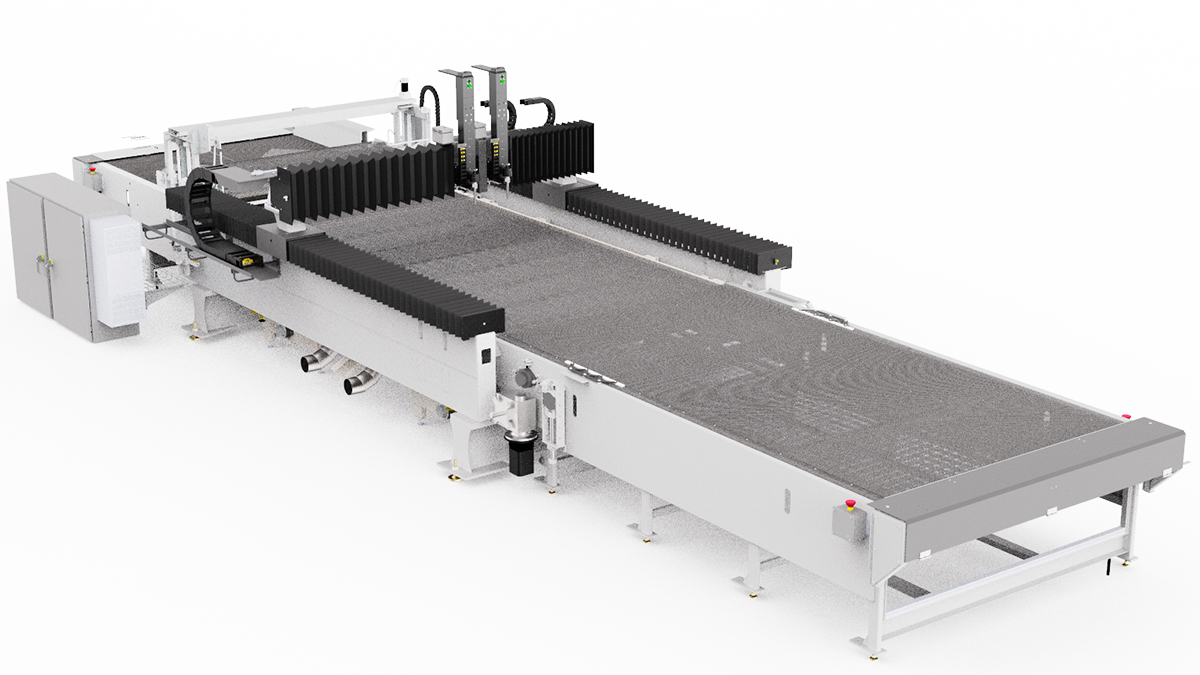

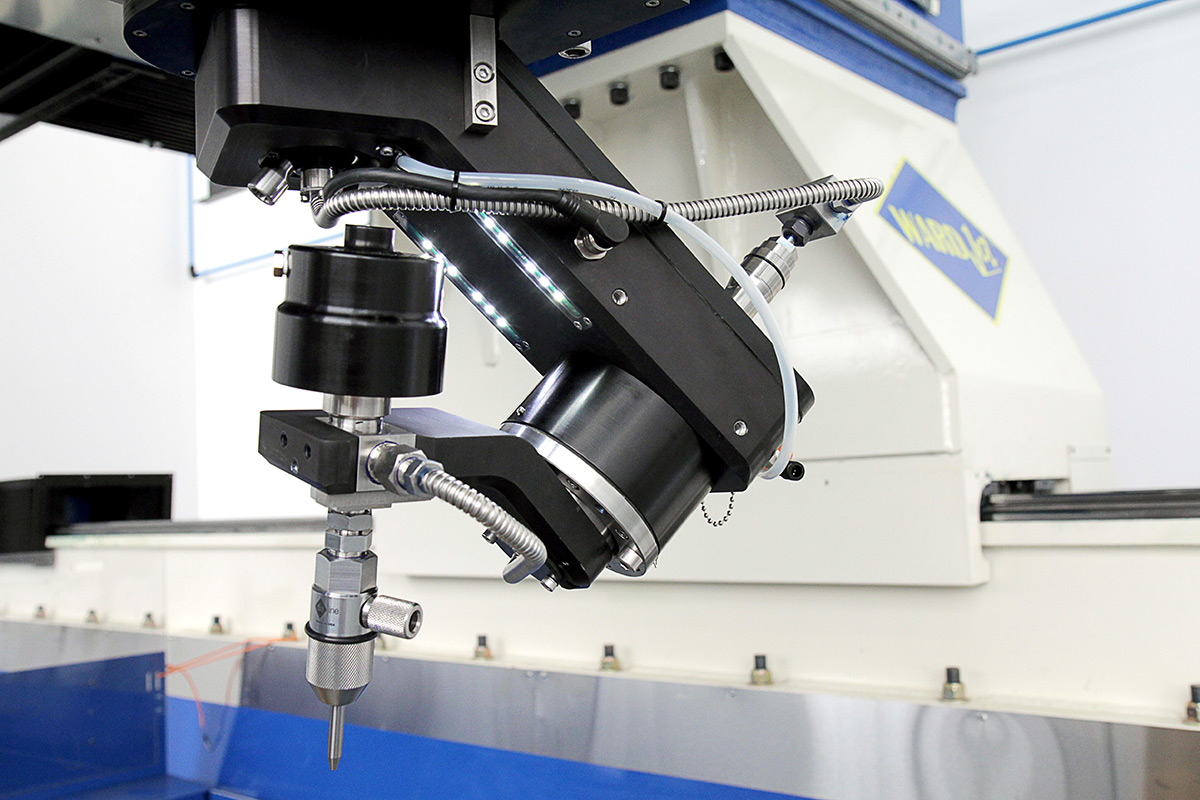

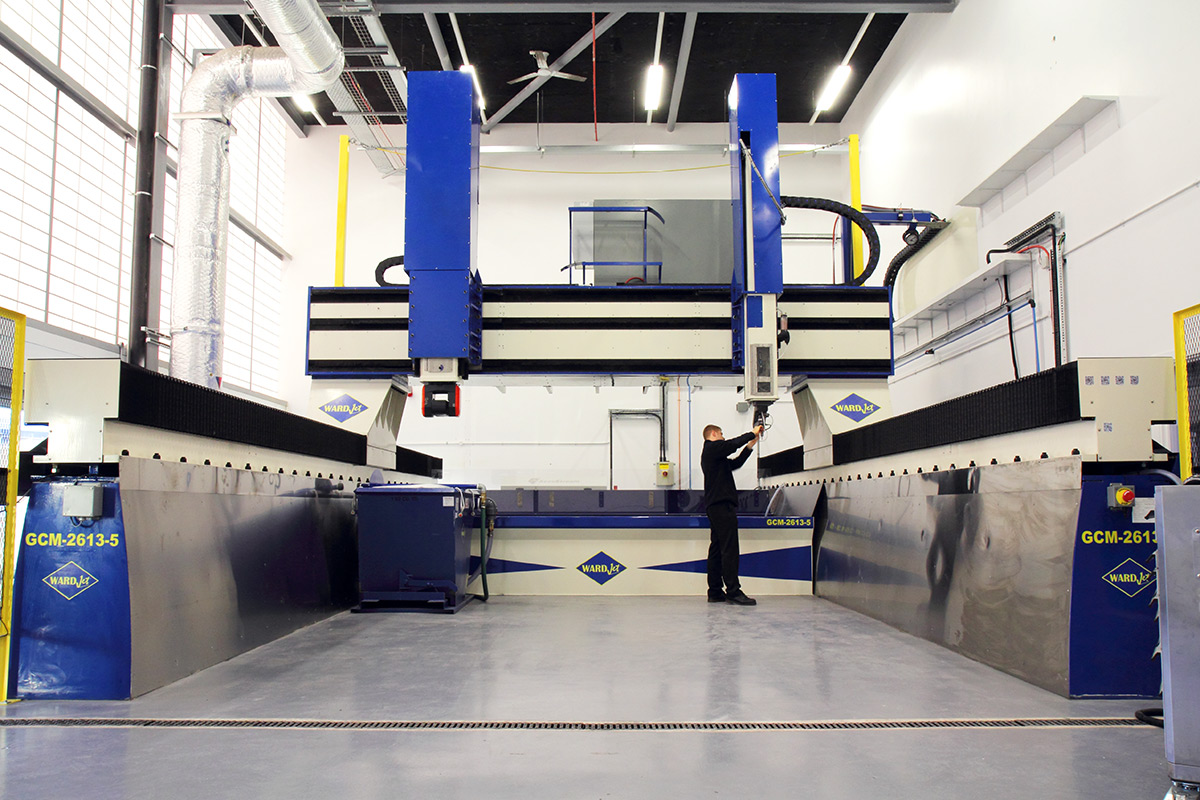

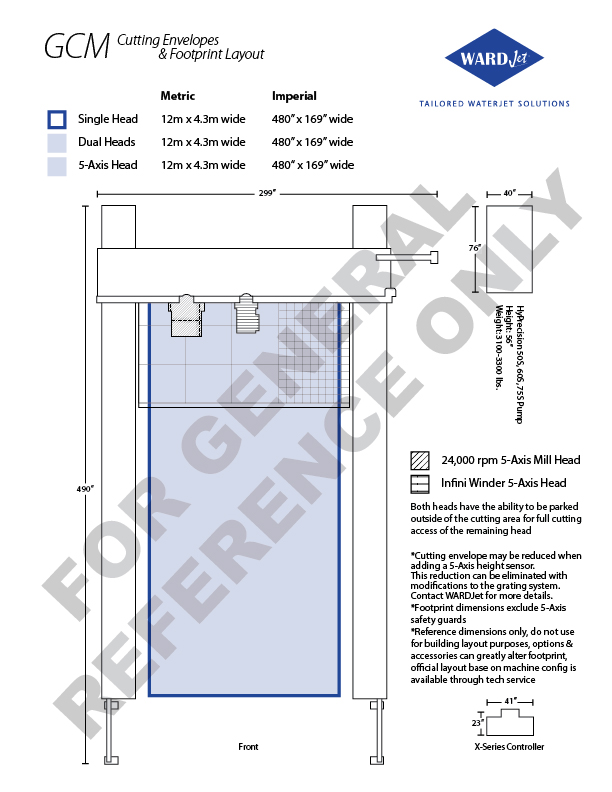

The GCM is one of the largest waterjets ever built by WARDJet, featuring both an Infini Winder 5-Axis head and a 5-Axis 24,000 RPM milling head for composite milling. The GCM has 5 feet of Z-Axis travel and is able to cut over the water table or over a part on the ground. The versatility this machine provides in terms of cutting and milling of composites is amazing. By combining both operations on a single, large-format system, operators can process composites without having to move the parts to a separate machine for milling. This helps to increase the accuracy of the parts as well as saving valuable time setting up a second machine.

Skontaktuj się

Dołącz do naszej drużyny

Od Twojej idealnej pracy dzieli Cię jedno kliknięcie. Zapoznaj się z naszymi aktualnymi możliwościami tutaj.