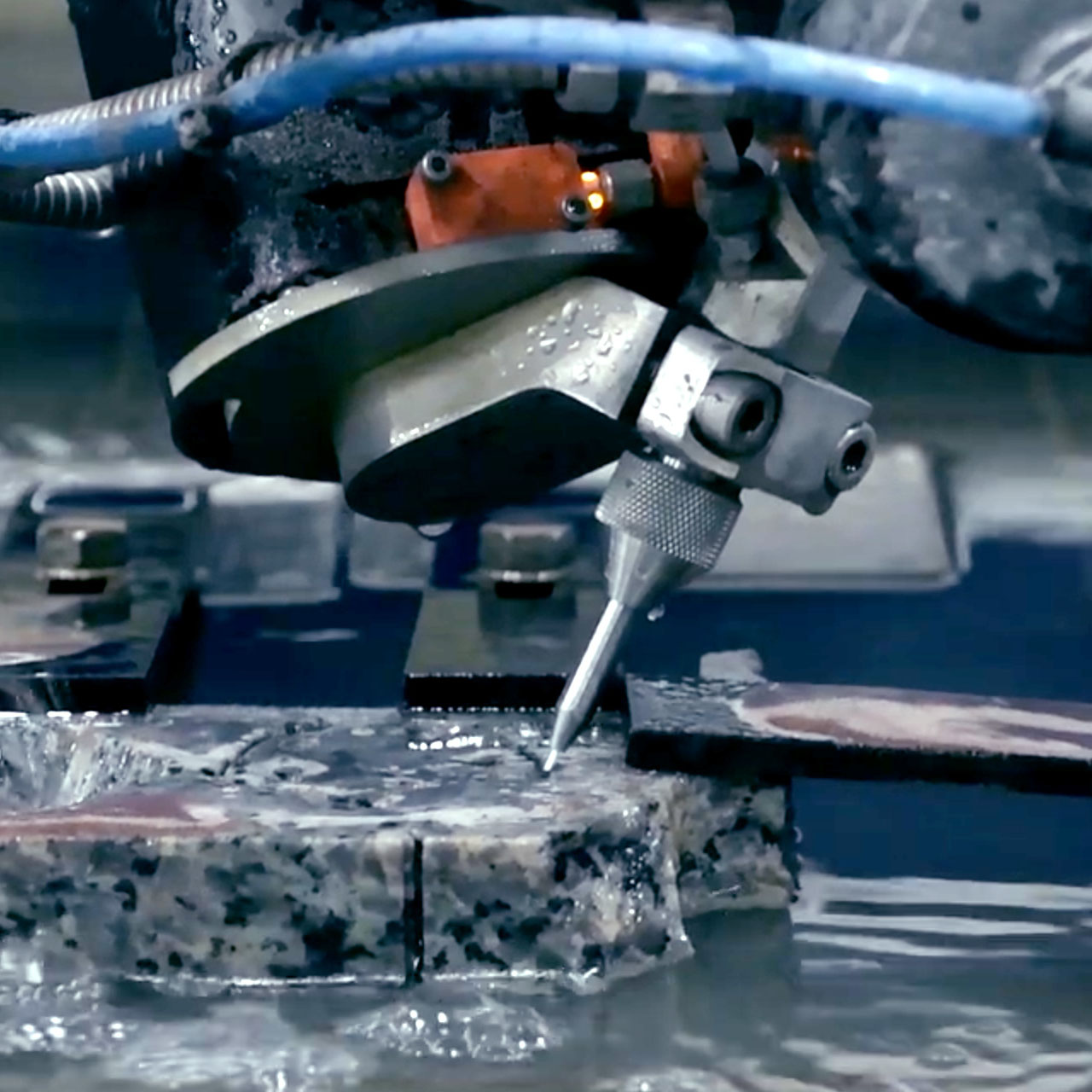

5-Axis Waterjet Cutting

Go beyond cutting bevels on flat stock — 5-Axis cutting opens up 3‑dimensional cutting abilities at angles from 0° to 90°.

Why 5-Axis?

Our 5-axis cutting systems unlock three-dimensional freedom. Instead of cutting only in 2D planes, you can now bevel, contour, taper, and shape intricate geometries with precision.

- Perform clean weld preps on thick metal plates

- Eliminate taper errors on complex materials

- Cut angles and contours without repositioning your part

- Process materials like foam, composites, steel, aluminum, stone, and more

This means faster setups, fewer secondary operations, and cleaner results — every time.

Apex 60 – Precision Taper & Bevel Control

The Apex 60 is designed for users who need precise control over taper and angle, especially when cutting flat materials or moderate bevels. With tilt capabilities up to 60°, it’s a proven solution for customers in signage, metal fabrication, plastics, and gasket production.

It’s ideal when you’re looking to:

- Maintain straight edges at high speeds

- Handle 5-axis cuts on flat sheet materials

- Add bevel capability to your production without overcomplicating your workflow

Simple, accurate, and fast — the Apex 60 gives you 5-axis functionality with maximum control.

Apex 90 – Full-Range Beveling with Extended Reach

The Apex 90 takes things further — with a full 90° of tilt and extended Z-axis reach. It’s built for advanced beveling, deep weld prep, and cutting into large, pre-formed or fixtured parts.

If you’re cutting parts that require:

- Bevel angles beyond 60°

- Full part rotation with 360° of C-axis travel

- Access into hard-to-reach geometries

- Contour cutting for aerospace, defense, or heavy equipment

…the Apex 90 delivers the reach, rigidity, and precision needed to get the job done.

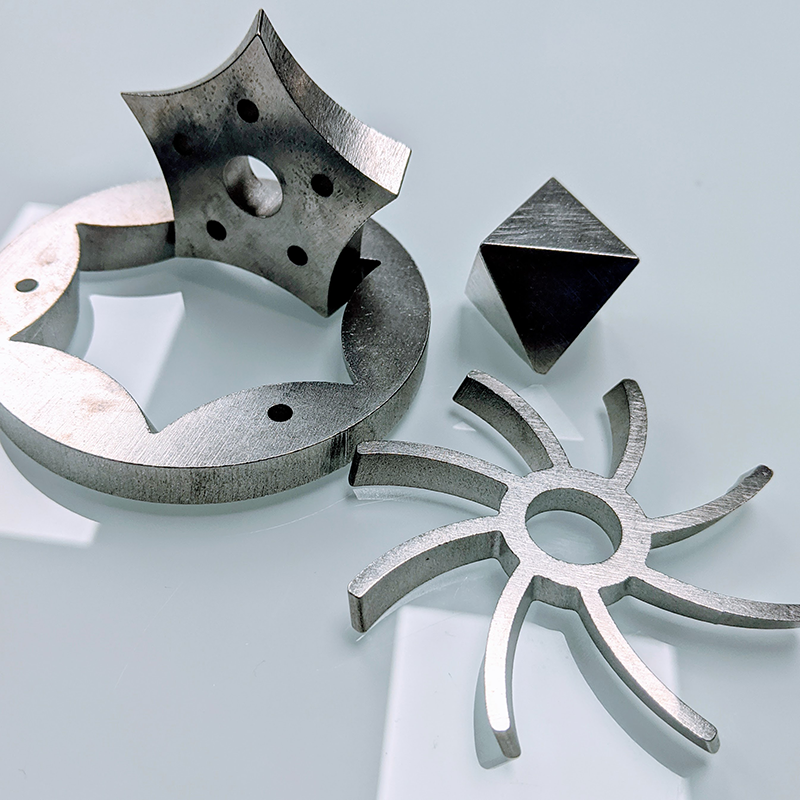

Process Any Material

Our 5-Axis cutting heads are just as versatile as our 3-axis cutting heads. You can process foam, metal, composites, stone and more.

Built for Industry

Whether you’re in aerospace working on composites and titanium, or fabricating large parts for defense and automotive, our 5-axis systems are built to meet your exacting standards.

Apex 60 excels in:

- Flat stock taper control

- Moderate bevel applications

- High-speed, tight-tolerance cutting

Apex 90 is built for:

- Deep bevel weld prep

- Complex 3D contours

- Large, fixtured, or thick components

Unlock 3D Shapes

Our 5-Axis cutting heads offer movement between 0° and 90°. This will enable you to control taper angle and create complex 3D designs. We have the Apex 60 as best option of 5-axis head.

Taper Angle Control

Use the Apex 60 cutting head to control the bevel on your cutting angles. This will ensure you have straight edges while cutting at higher speeds. For example, we have clients who perform weld preparation with their 5-axis and need a flat edge on their weldment.

Accuracy

Positioning accuracies of +/- 1.5 arc minutes (+/-0.0249 degrees) make the Apex 60 the most accurate 5-Axis cutting head.

Speed

Depending on the waterjet system and materials, speeds can be up to 2,000 in/min to keep up with higher output.

Versatility

Add 5-Axis in addition to 2D heads for the ultimate mix of high production and versatility.

See It in Action

Experience the cutting difference with a live virtual demo or send in your material for a custom test cut.

Use our expertise to find the right configuration for your process, part size, and output goals. Our application engineers are ready to help you dial in your ideal setup.

Get in touch

Product Brochures

Get a copy of WARDJET's latest product brochure. Learn all about our extensive range of WARDJet CNC waterjets. Choose between our 6 big series - A-Series, X-Series, M-Series, H-Series, J-Series, and L-Series.