Stress-free Metal Fabrication

Industry

Metal & Alloys

Client

Cutlass Mechanical Engineering

Overview

Cutlass Mechanical Engineering, metal fabrication specialists in the south of England, were sourcing a system specifically for two bridge restoration projects. These projects required hundreds of hours of heavy plate processing. Reliability and high production were key.

Process multiple metal types/alloys and thicknesses in one pass, with a single tooltip.

APEX 60 allows for increased cutting speed while preserving edge quality and straightness.

Materials: Steel, Stainless, Aluminum, Titanium, Brass, Inconel, Copper.

Client’s Needs

For the safety and longevity of bridge restoration projects, it was essential to produce a high volume of thick parts without introducing stress into the material. With over 3,000 half-inch-thick parts required for one job alone, Cutlass sought a way to achieve that level of production using a single system.

Our Solution

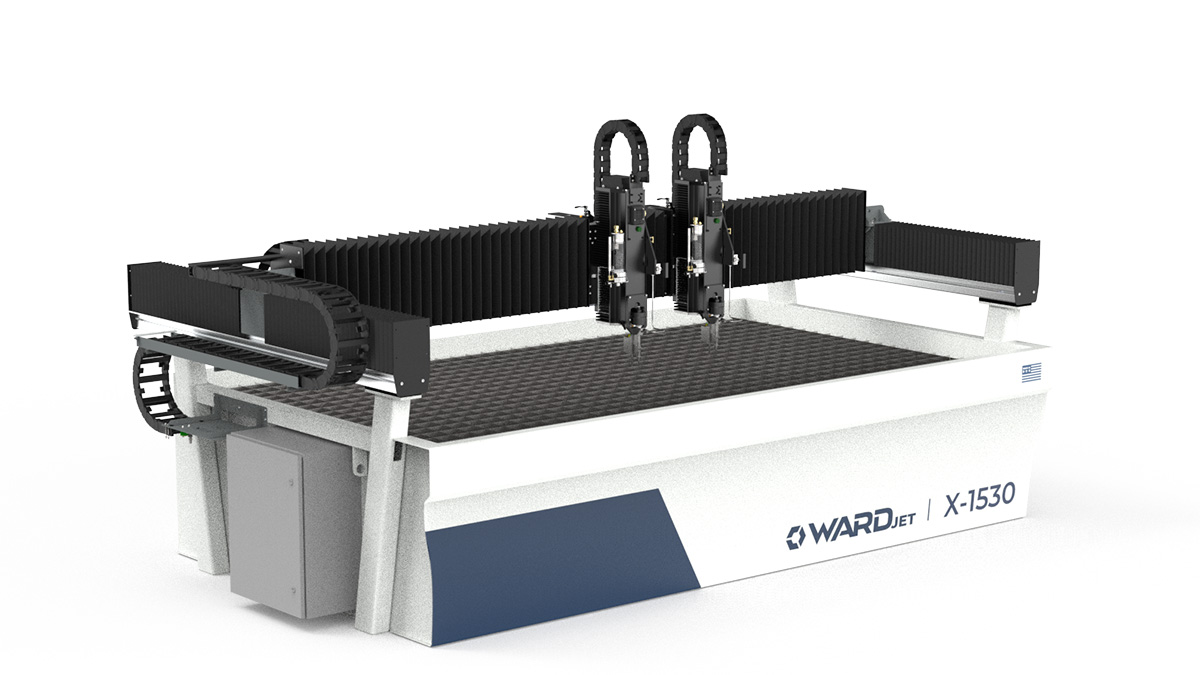

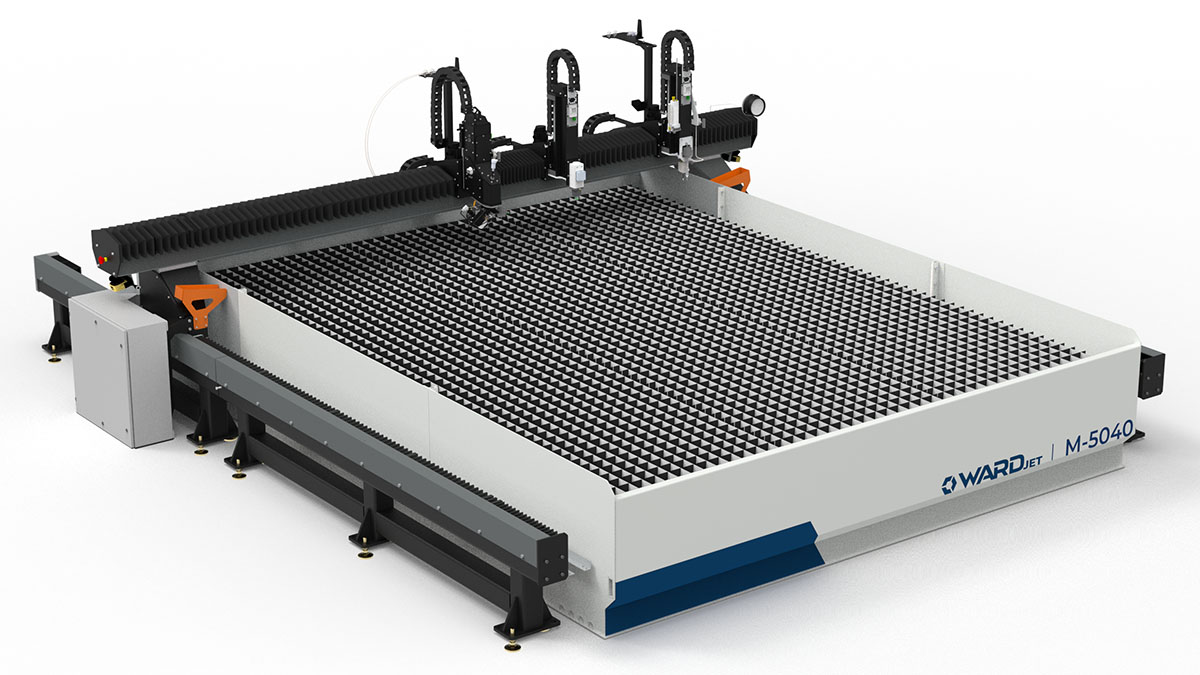

WARDJet provided Cutlass Mechanical Engineering with a dual headed Z-2543. This system allowed for Cutlass to double their production by using both heads at once. The mechanical accuracy of WARDJet systems is key to multiple head production. Cutlass was able to get maximum output out of a single system and produce all the needed parts for their restoration projects.

Suggested Products

Partnerships

Get in touch

Product Brochures

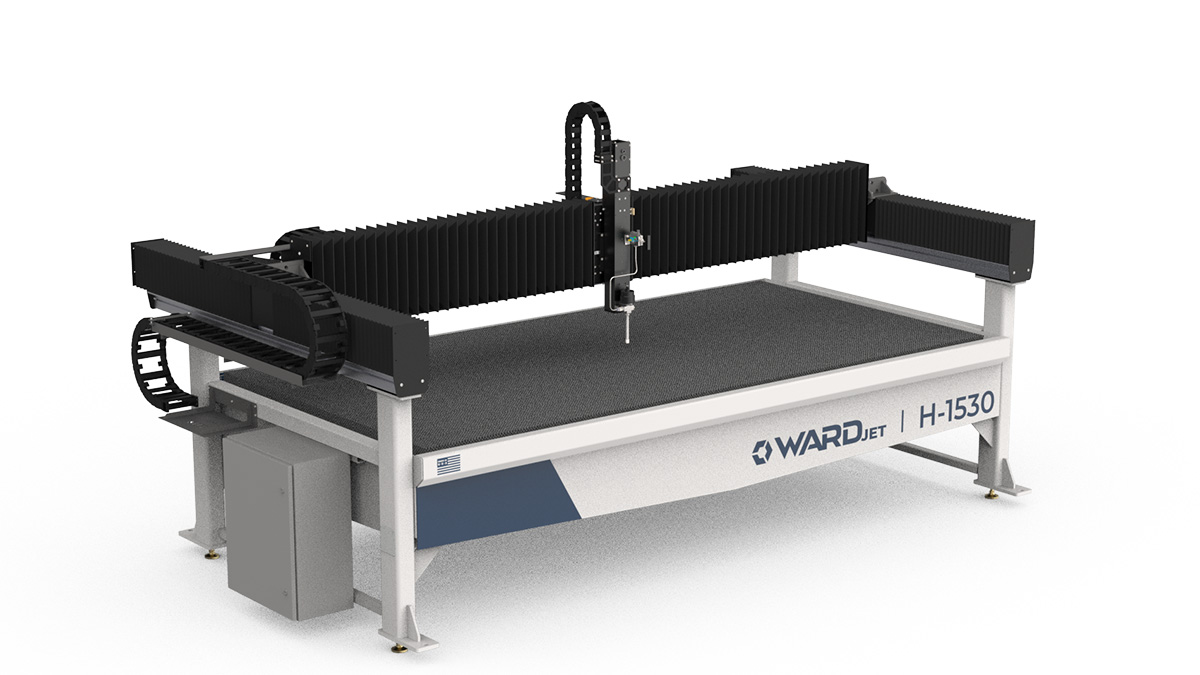

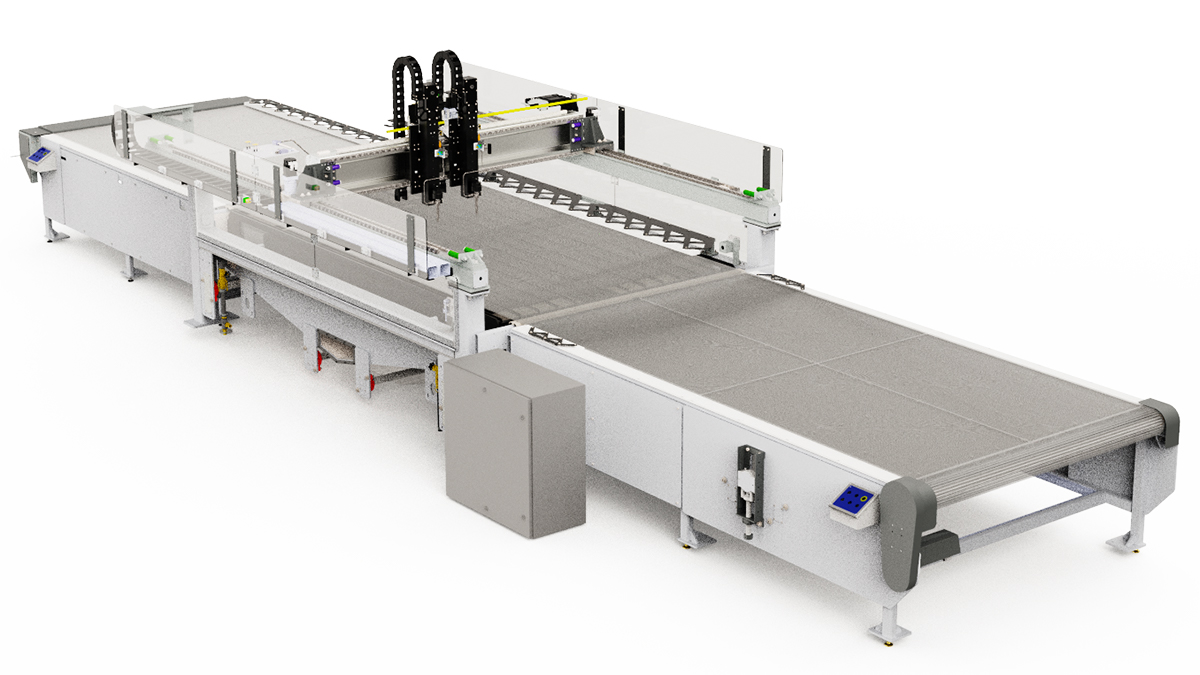

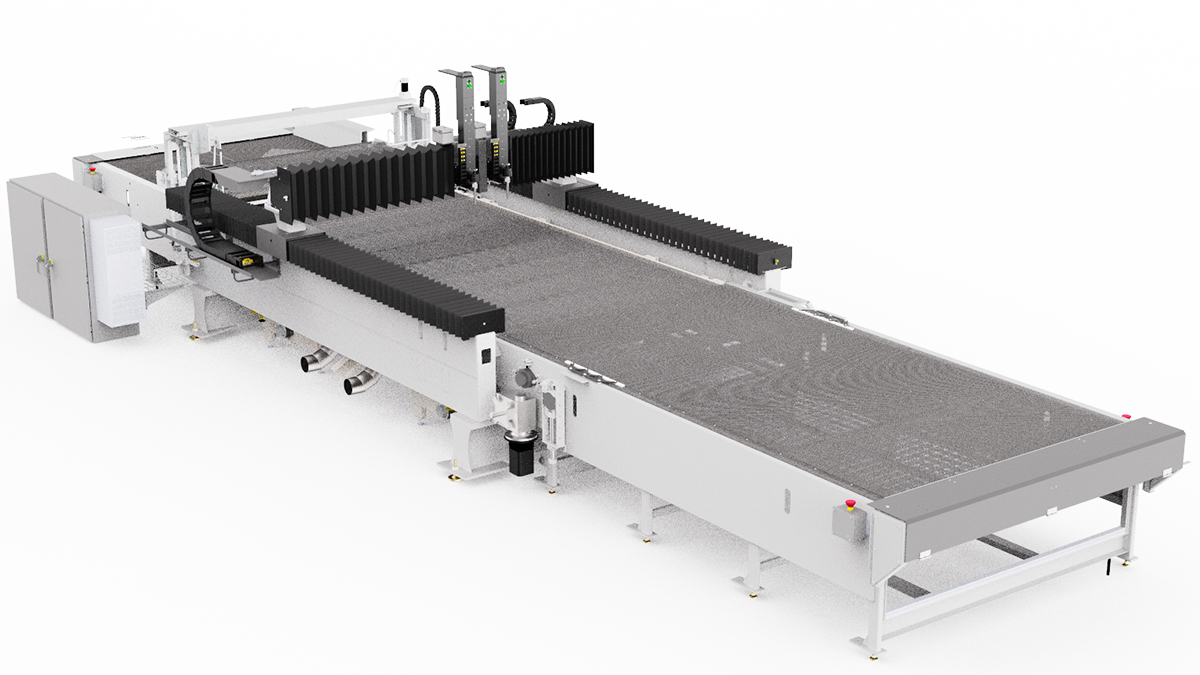

Get a copy of WARDJET's latest product brochure. Learn all about our extensive range of WARDJet CNC waterjets. Choose between our 6 big series - A-Series, X-Series, M-Series, H-Series, J-Series, and L-Series.