Convert Better

Industry

Foam & Rubber

Client

Amcon (American Converters)

Overview

Our client is a leading foam fabricator, providing converting services over one of the widest arrays of foams in the industry. They were looking for a purpose-built system to allow them lightning-fast production while minimizing downtime between cuts.

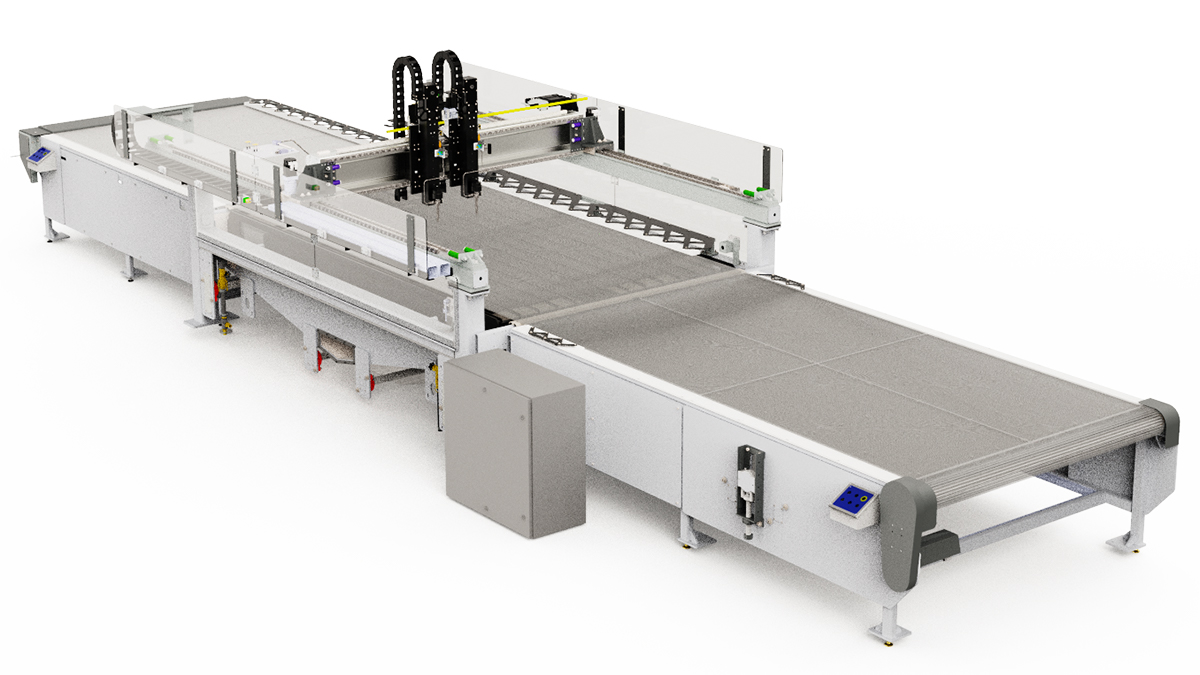

High-Speed machines allow for higher production and lower per part cost.

Industry-exclusive sloped tank design and chain feed system allow for continuous, high-volume production.

Materials: Cross-linked Polyethylene foams (XLPE), Zotefoams, Polyethylene Planks, Neoprene, Silicone Rubber.

Client’s Needs

Our client was looking to add a system to their shop to allow for high volume water-only production, without the need to stop and clean out waste. They needed the ability to quickly transition from small runs to large, over a variety of materials without losing time loading, unloading, and cleaning the system.

Our Solution

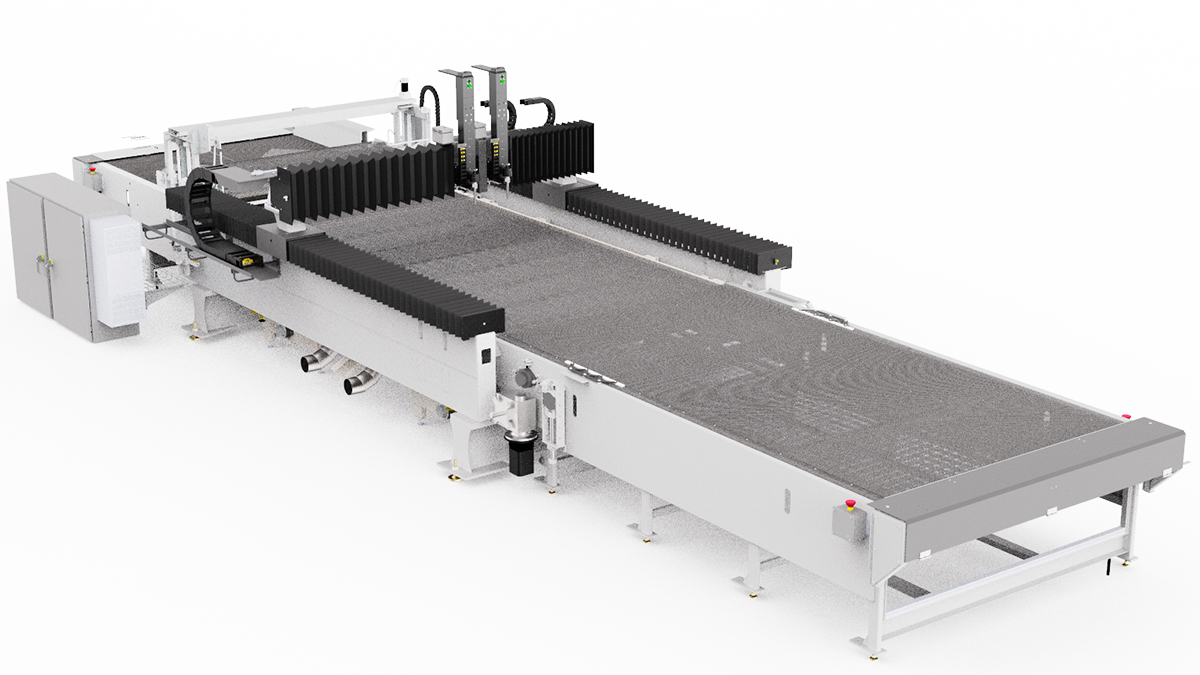

WARDJet provided the client with our industry exclusive L-3018. This unique system features a linear drive system to provide motion up to 7000 inches per minute. The chain feed system with in and out-feed tables allowed the client to continuously cut without the need to stop for loading and unloading. WARDJet’s unique sloped tank design of the L-Series allowed the client to vitally eliminate wetting of the material. All these features combined to give our client a huge competitive advantage.

Suggested Products

Partnerships

Get in touch

Product Brochures

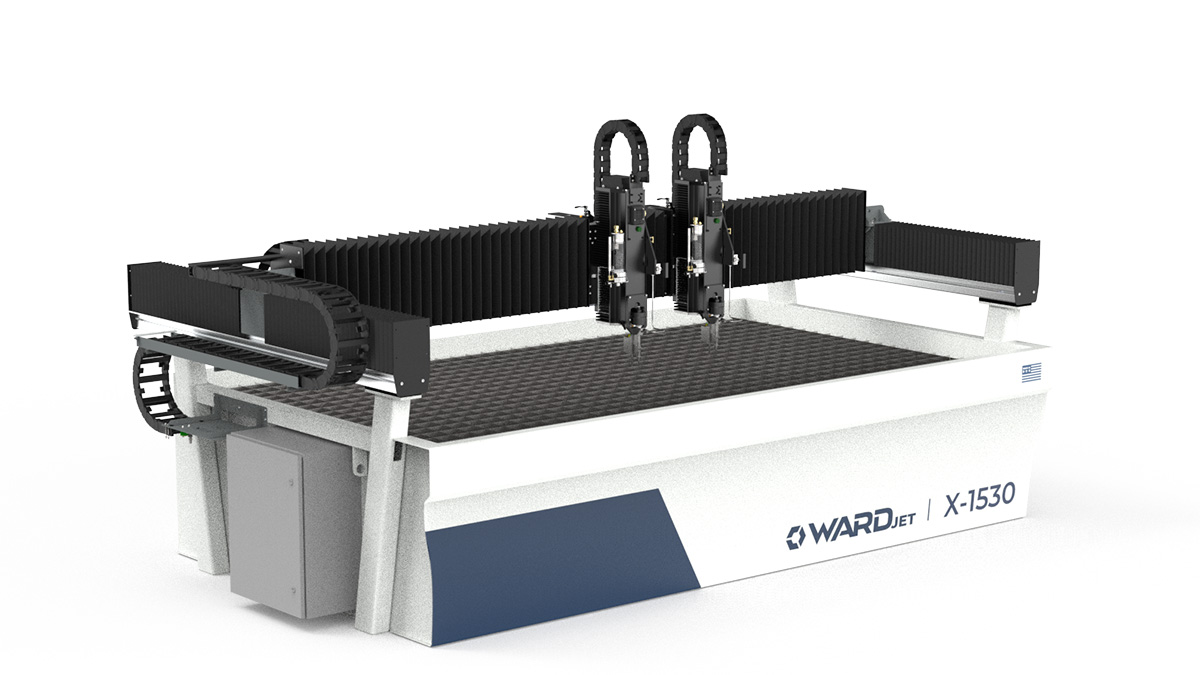

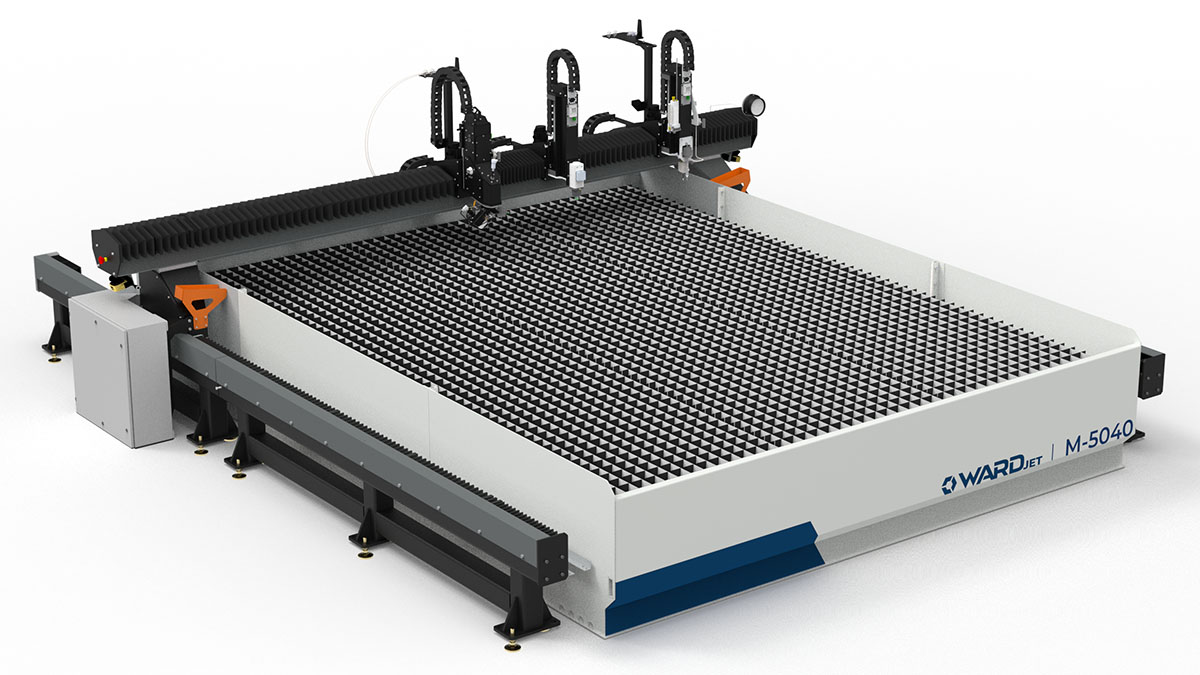

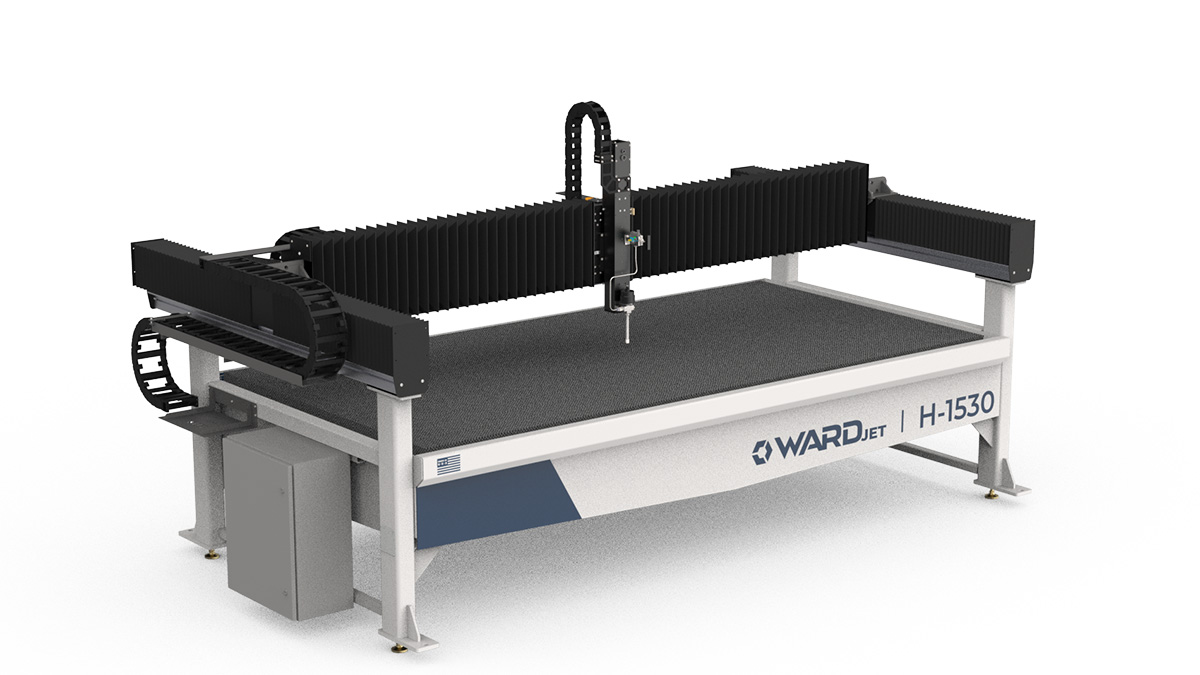

Get a copy of WARDJET's latest product brochure. Learn all about our extensive range of WARDJet CNC waterjets. Choose between our 6 big series - A-Series, X-Series, M-Series, H-Series, J-Series, and L-Series.