Cleaner Cutting Every Time

Industry

Composite & Plastics

Client

Defense Manufacturer

Overview

In 2018, we were contacted by a premiere manufacturer of composite body armor. They needed a solution that could process advanced composites with precision and speed. Our WARDJet Z-Series enabled them to seize new growth.

Our waterjets reduce the risk of hazardous dust during composite processing.

Process a wide variety of composites using the same waterjet tool.

Material: Ultra High Molecular Weight Polyethylene( UHMW), Carbon Fiber, Fiberglass, Multi-ply Polyethylene.

Client’s Needs

Our client protects the lives of police officers and soldiers using their composite body armor. Precision is paramount when processing these protective panels. Furthermore, the advanced materials continue to evolve and improve which requires a flexible manufacturing process.

Our Solution

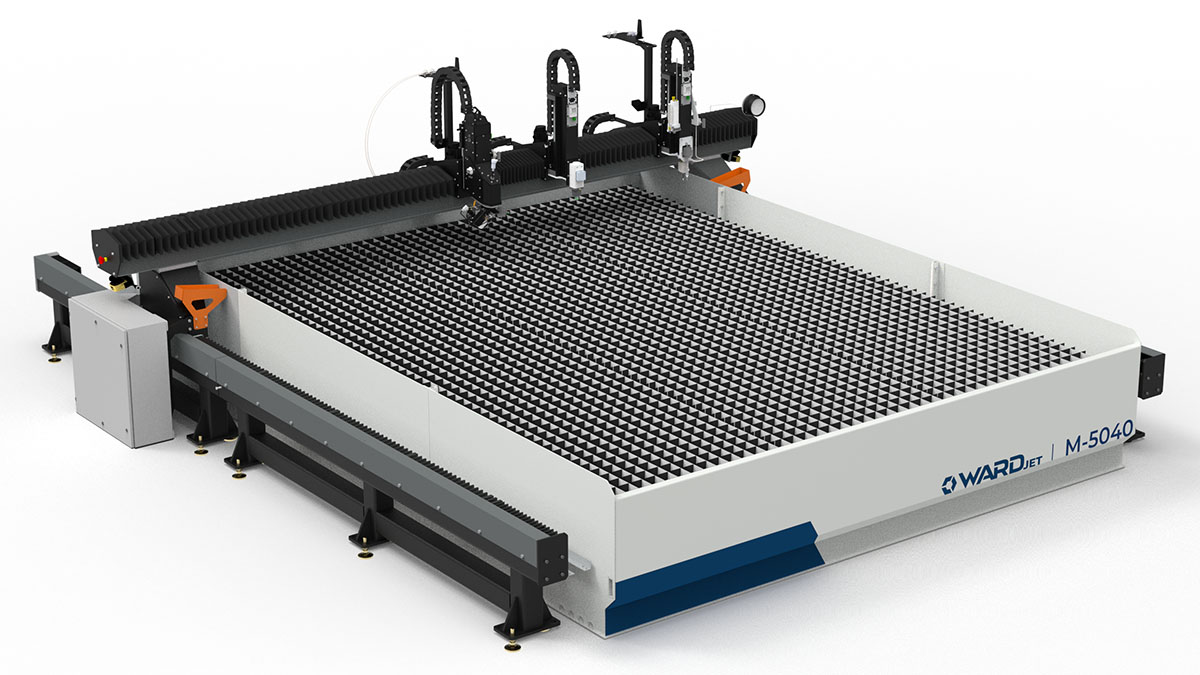

Our WARDJet Z-Series (now known as M-Series) fit the needs of this dynamic manufacturing environment. The 5-Axis cutting head produces complex and accurate parts with ease. The abrasive waterjet allows them to take on new advanced materials with the same tool. Lastly, the large cutting envelope enables for a high volume of work with one set up.

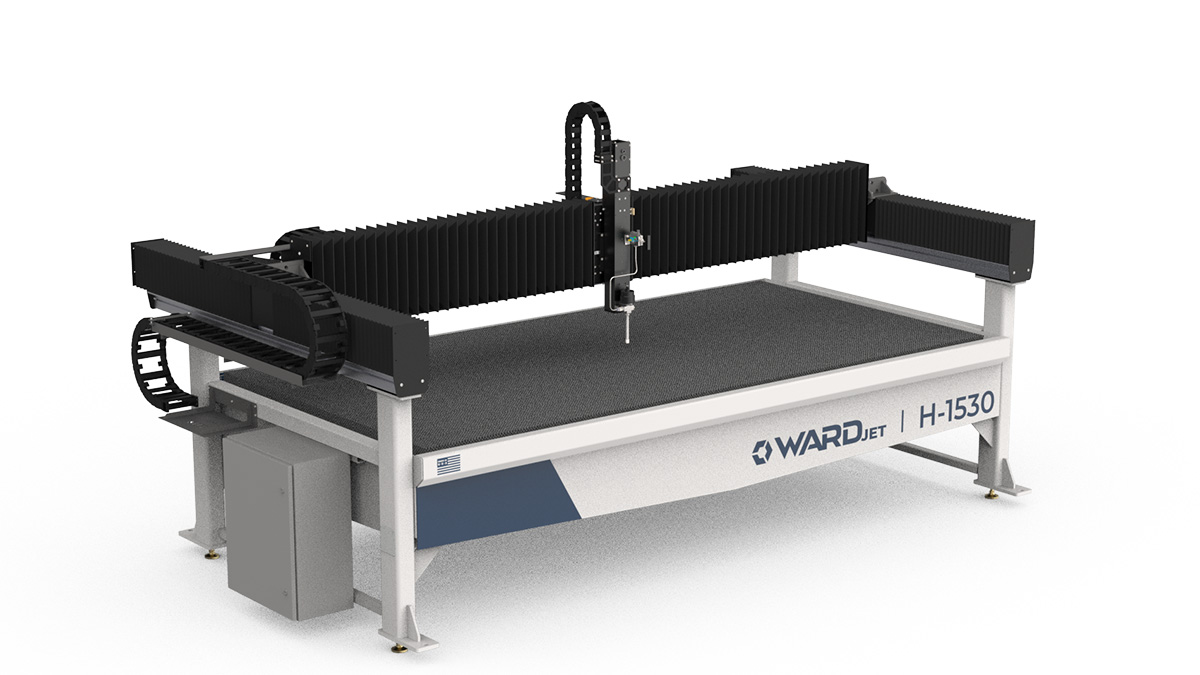

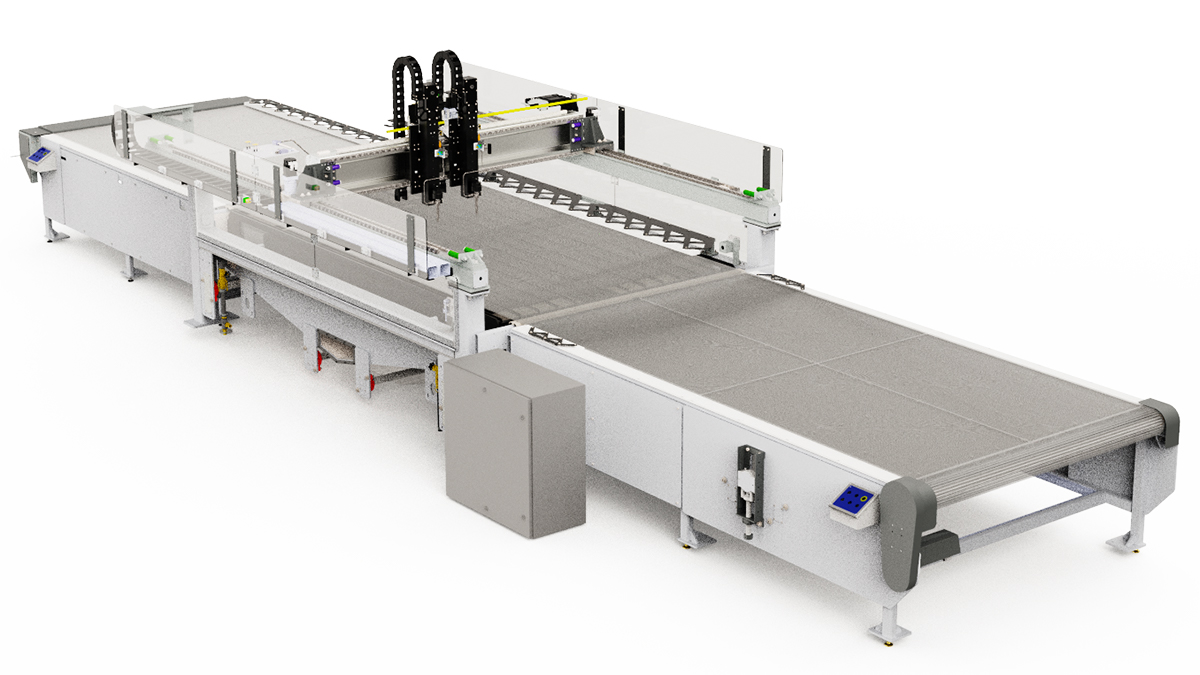

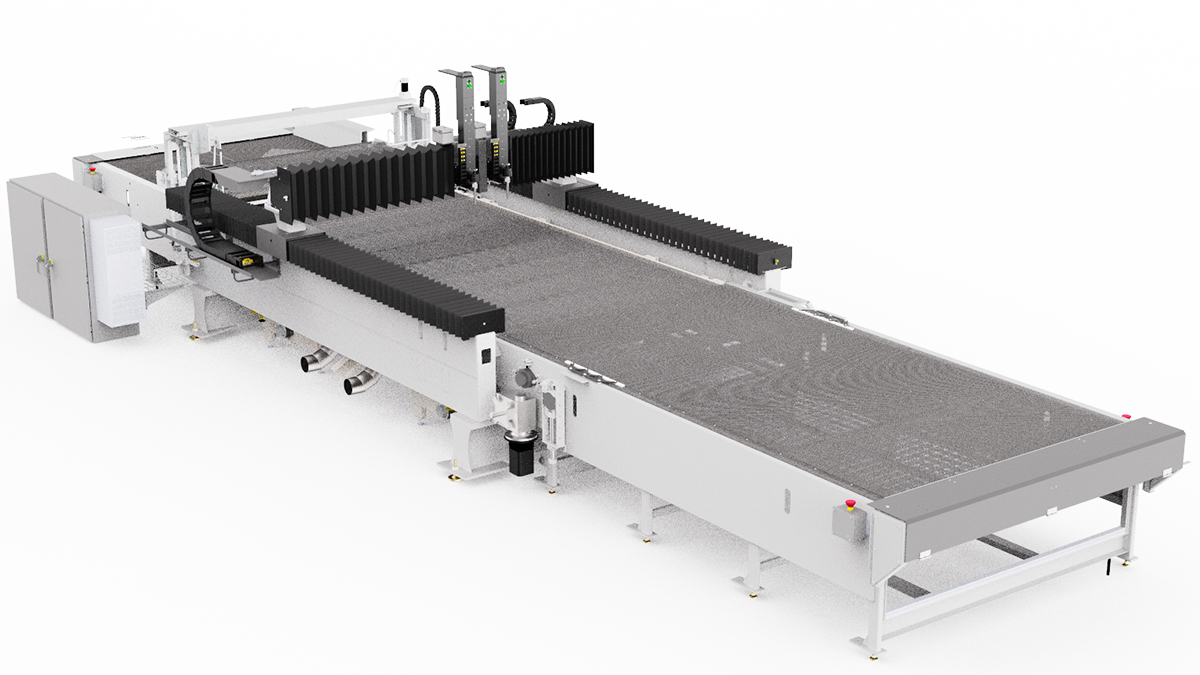

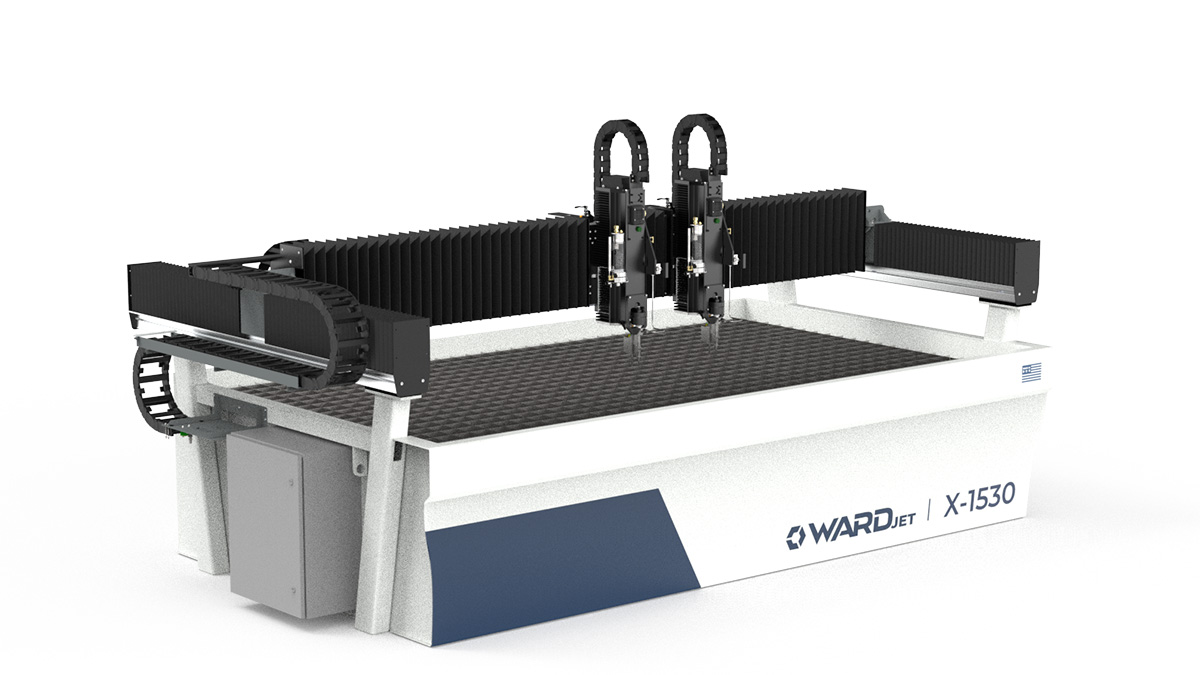

Suggested Products

Partnerships

Get in touch

Join our team

We are always looking for knowledgeable people who are passionate about delivering an exceptional customer experience. Let’s talk!