Soar to New Heights

Industry

Aerospace & Defense

Client

Top Commercial Aerospace Supplier

Overview

Our client needed to trim and add features to two very complex dimensional parts for a commercial aerospace company. The application would have to be waterjet, as traditional gantry and robot capabilities were unable to complete the task.

No heat-affected zone allows for processing of advanced materials without compromising material structure.

Ability to easily transition from thin to thick materials without changing tooltips.

Materials: Aluminum, Steel, Carbon Fiber, Proprietary Alloys.

Client’s Needs

Our clients’ parts were very large pieces with trimming and features needing to be made in all areas of the part. Each part was 10ft wide and over 3ft tall. Some of the features would need to be cut within the part, outside of the reach of most traditional waterjet applications.

Our Solution

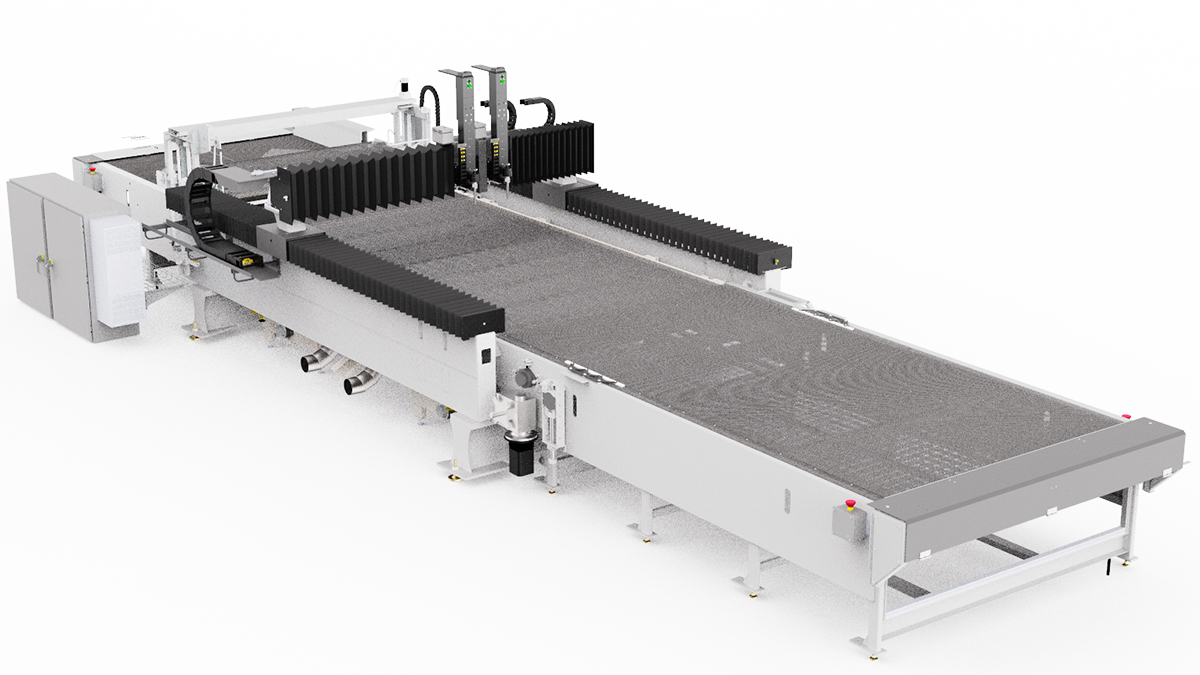

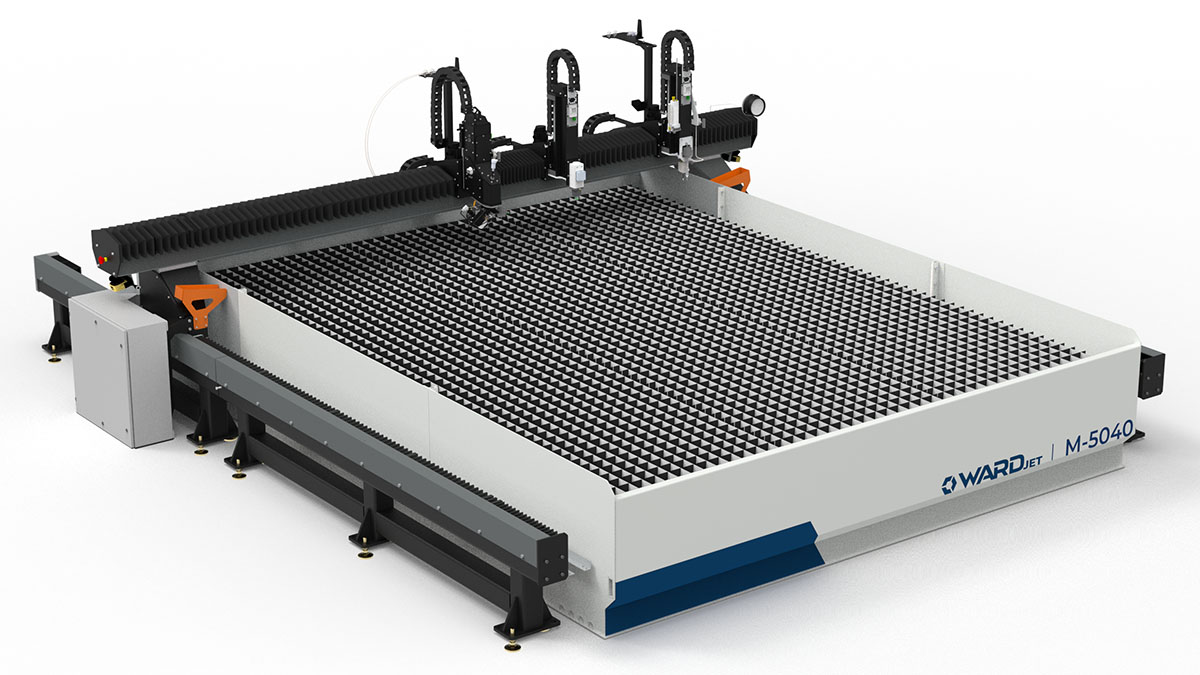

WARDJet partnered with the client to tailor a large format 14ft by 20ft R-Series waterjet system. This system featured 3ft extended Z-travel and extended cutting head reach of an additional 18in. WARDJet also provided a modified tank with fixtures to hold the specific parts being processed, with additional work volume for traditional waterjet cutting in the rear of the tank. WARDJet’s team also wrote new 5-axis kinematics for the extended 5-axis head and continues to partner with the customer on continued Aerospace waterjet projects.

Suggested Products

Partnerships

Get in touch

Product Brochures

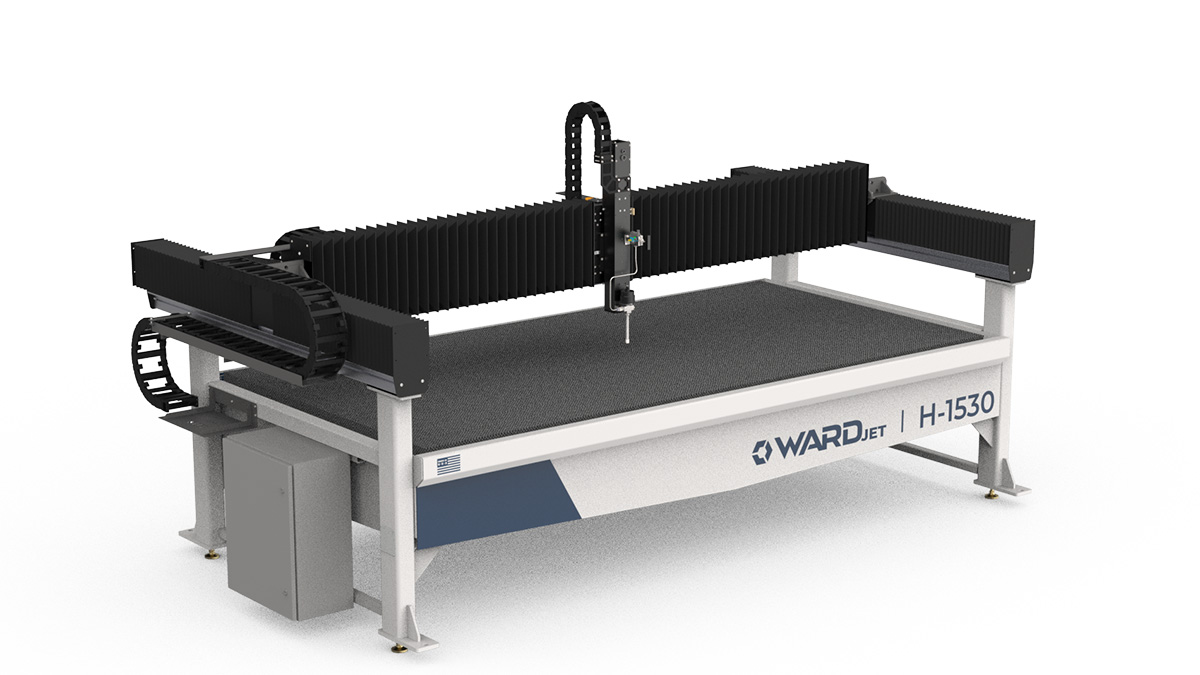

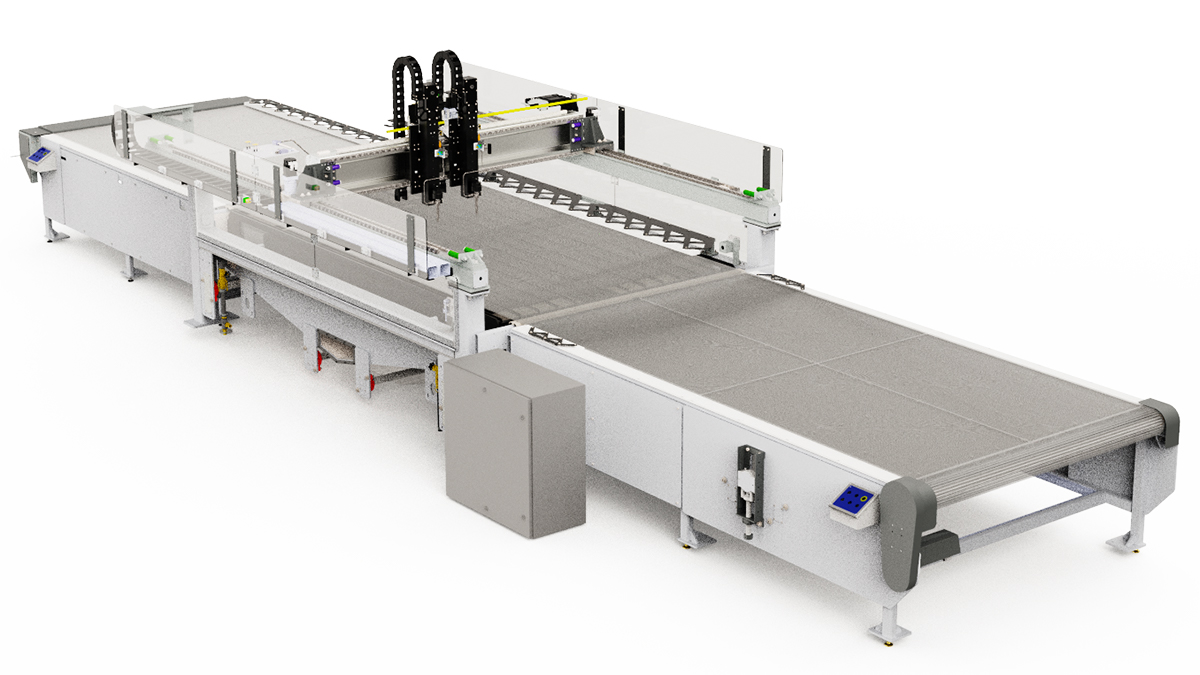

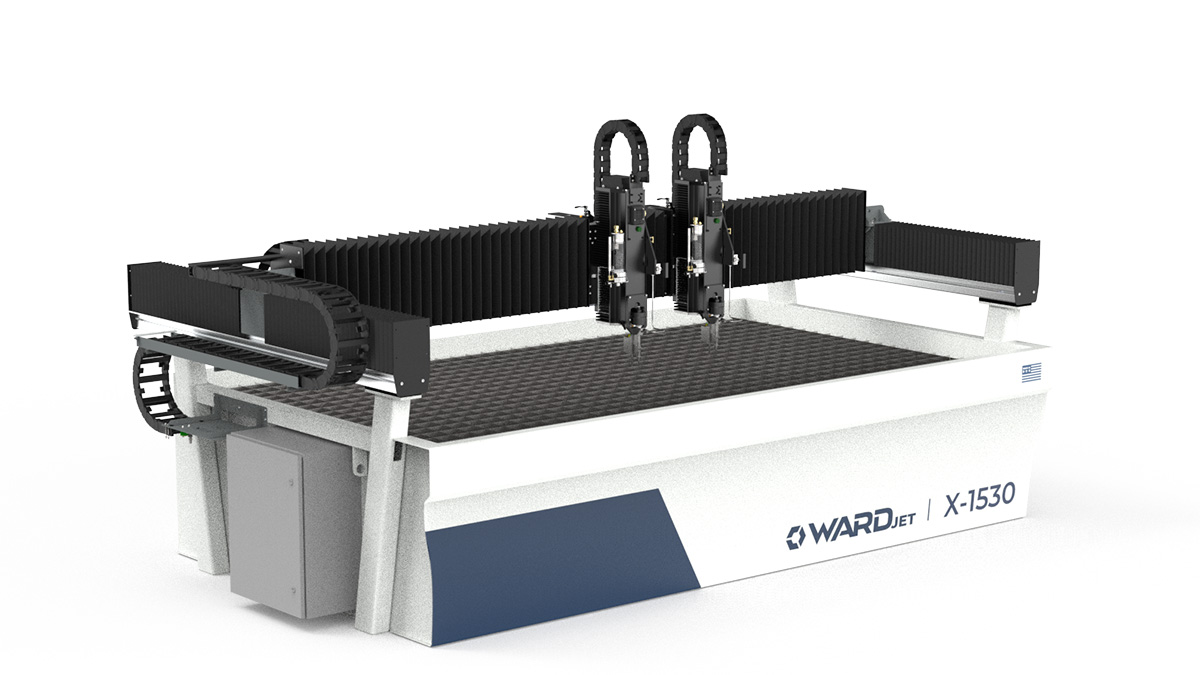

Get a copy of WARDJET's latest product brochure. Learn all about our extensive range of WARDJet CNC waterjets. Choose between our 6 big series - A-Series, X-Series, M-Series, H-Series, J-Series, and L-Series.