Reading time: ~ 5 minutes

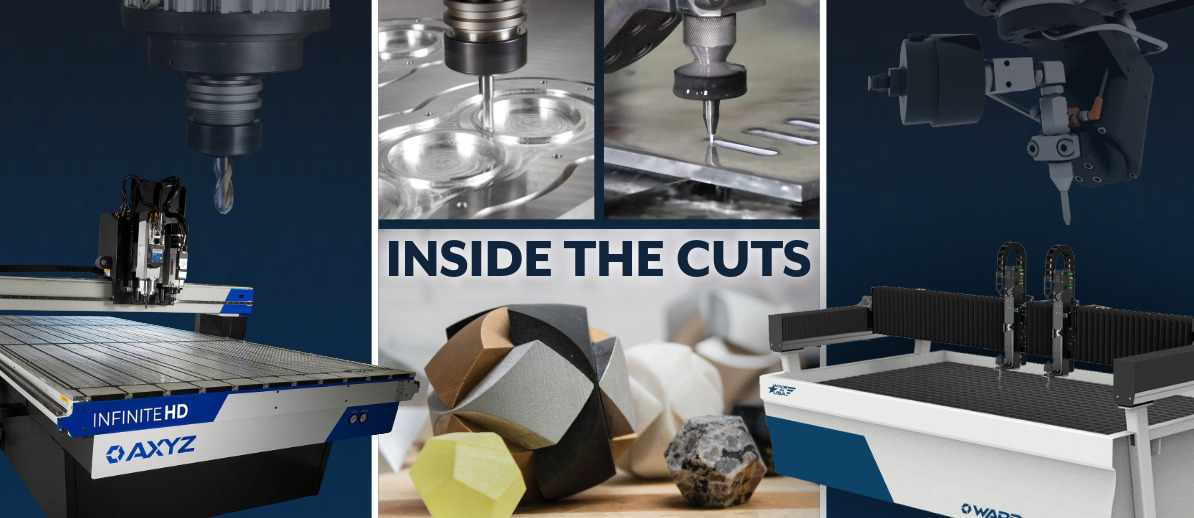

Real samples, real results. You held these parts at FABTECH, and here’s exactly how we cut them. We paired materials with our WARDJet Waterjets and AXYZ Routers to showcase a full range of cutting capabilities, from brittle glass and clear plastics to aluminum on both platforms. Use the process plans below to recreate the same quality back in your shop.

WARDJet Waterjet Samples

We started at the waterjet to highlight true “cold cutting”: no heat-affected-zone (HAZ), square edges, and smart pierce strategies. These three samples (polycarbonate, aluminum, and glass) mirror common shop challenges while showing the edge quality you can expect straight off the table.

Polycarbonate: Smooth, Stress-Free Edges

Goal: Deliver smooth edges with clean corners and crystal clarity—no secondary polishing.

How we made it

- Cut: 0.014″ orifice / 0.040″ nozzle at 60,000 PSI.

- Program: Short lead ins and gentle lead outs to avoid witness marks.

- Run: Controlled traverse and standoff for a clear, even edge.

Result: Chip-free, square edges and clear faces with minimal postop.

Why WARDJet: MOVE CNC makes dialing cut parameters straightforward; platform motion is consistent, and abrasive/water settings are easy to tune for plastics.

Aluminum: Tight Profiles, Minimal Burr

Goal: Hold size with a consistent edge while keeping burrs low and heat input near zero.

How we made it

- Cut: 0.014″ orifice / 0.040″ nozzle at 60,000 PSI.

- Program: Lead ins/outs and proper cornering to preserve edge quality.

- Run: Stable standoff and feed to maintain a uniform kerf.

Result: Accurate parts with a smooth edge finish and a light, even burr. Easy to break by hand or quick deburr.

Why WARDJet: Robust motion paired with 60,000 PSI pump capacity makes metal cutting consistent; SmartRemove abrasive handling reduces downtime between jobs.

Glass: Chip-Free Edges, Protected Corners

Goal: Avoid cracks at pierce points and leave profiles clean enough for install.

How we made it

- Pre-pierce: 10,000 PSI low pressure pierce at start points.

- Cut: 0.014″ orifice / 0.040″ nozzle at 60,000 PSI for the profiles.

- Program: Smooth lead outs on closed contours to protect corners from chipping.

Result: Clean, readable edges and intact corners with minimal frosting—ready for wash and install.

Why WARDJet: MOVE CNC + CAM workflows support low pressure pierce followed by full pressure cutting (best practice for brittle materials like glass).

With the waterjet work complete, we turn to routing to extend the sample set. Waterjet establishes edge integrity and dimensional accuracy without heat; routing demonstrates throughput, multi-tool workflows, and refined surface finishes on aluminum, acrylic, and foam. The next AXYZ Trident process plans mirror the show floor setups and are ready to reproduce in your shop.

AXYZ Router Samples

Routing shines when you need tool variety, 3D surfacing, engraving, and fast cycle times. The AXYZ Trident platform let us combine automatic tool changes, zoned vacuum, and rigid servo motion to run three very different materials.

Aluminum — Clean 3D Curves + Sharp Branding

Goal: Produce a smooth, rounded surface and a crisp logo while keeping the cycle tight and burrs light.

How we made it

- Round the contours (3D): 0.5″ ball nose at 100 IPM / 18,000 RPM to generate even scallops.

- Cut the logo: 0.125″ tool at 70 IPM / 18,000 RPM for tight radii and flat floors.

- Profile the perimeter: 3/8″ O-flute (dry) at 100 IPM / 18,000 RPM for the external edge.

Result: Clean 3D curves with sharp branding; only a light deburrs as needed.

Why Trident: Rigid servo drive for consistent scallops, fast ATC for logo/profile tool changes, and dry routing capability for non‑ferrous work.

Acrylic: Glossy Edges, Crisp Engraving

Goal: Smooth edges and clean corners with sharp engraving. Minimize heat and recut to keep the acrylic clear.

How we made it

- Engrave first: 1/16″ ball nose to lock in fine detail.

- Rough the shape: 0.25″ O-flute upcut at 100 IPM / 24,000 RPM (conventional) to remove bulk.

- Secondary roughing pass: Repeat the same toolpath to clear any recut chips.

- Finish pass: Dry cutting tool at 30 IPM / 17,000 RPM for a clear, smooth edge.

Result: Glossy edges and sharp engraving with minimal cleanup.

Why Trident: ATC for seamless tool swaps, smooth servo/helical motion for optical, clear edges, and zoned vacuum to keep small acrylic parts stable.

Foam: Fast, Clean Pockets

Goal: Pocket quickly, keep walls clean and profiles square, and reduce post‑processing to a quick vacuum and brush.

How we made it

- Bulk pocketing: 3/8″ straight-flute at 150 IPM / 18,000 RPM (conventional).

- Detail cleanup: 0.125″ straight-flute at 150 IPM / 18,000 RPM for small pockets and features.

- Final profile: Light finishing pass to square edges and leave a tidy silhouette.

Result: Crisp pockets and profiles with minimal fuzz.

Why Trident: Highspeed routing with strong vacuum hold-down for light stock; the router/knife platform is ideal for foam workflows.

Ready to Reproduce These Results?

Want the exact toolpaths or a live demo on your material? Our applications team can walk you through setup on WARDJet waterjets and AXYZ routers, from parameter selection to work-holding and finishing.

- Explore WARDJet waterjets: https://www.wardjet.com/get-a-quote/

- Explore AXYZ routers: https://www.axyz.com/get-a-quote/