Motion Control. Reimagined.

Included standard with the M-Series, MOVE™ is hands down the simplest CNC software available today and features technology like drag-and-drop part loading and even part queueing.

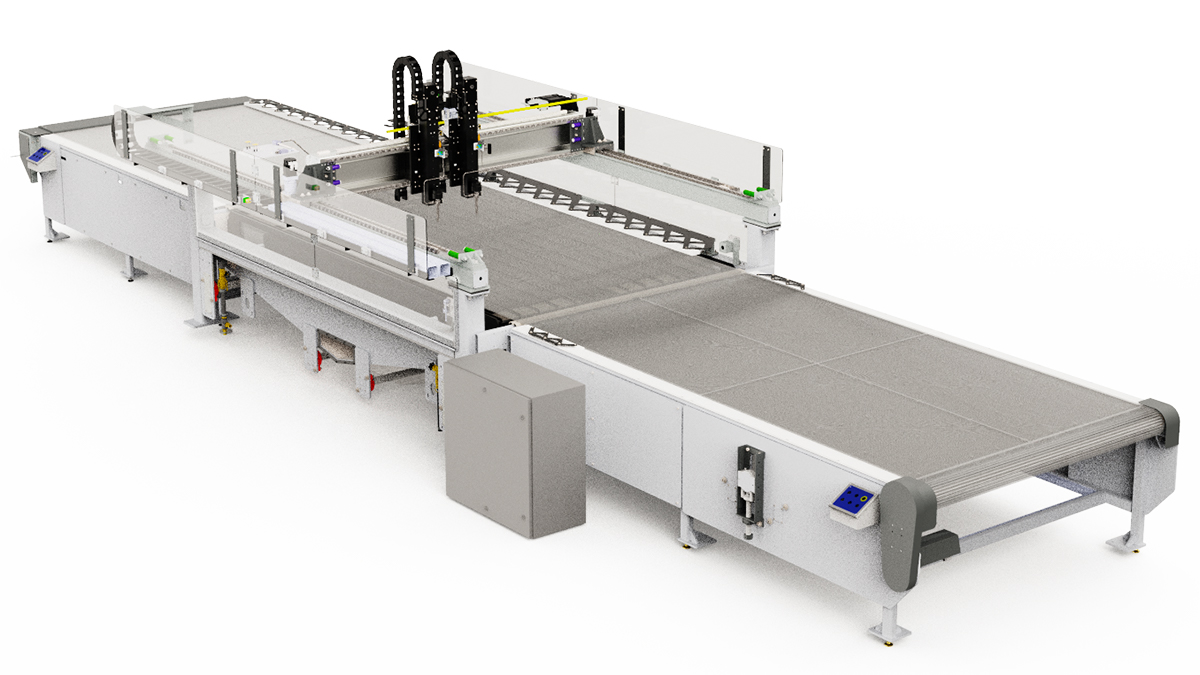

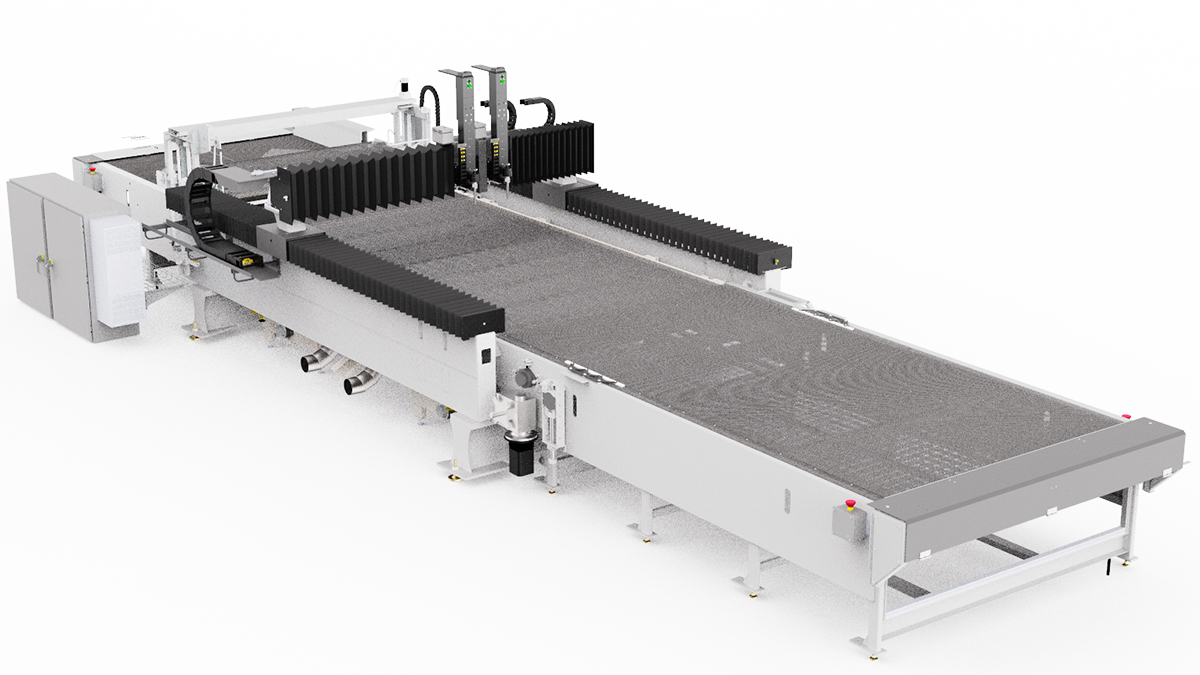

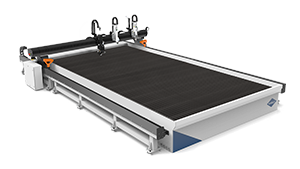

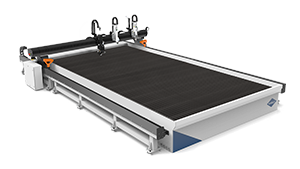

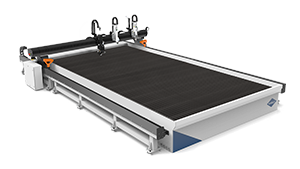

Designed for Production

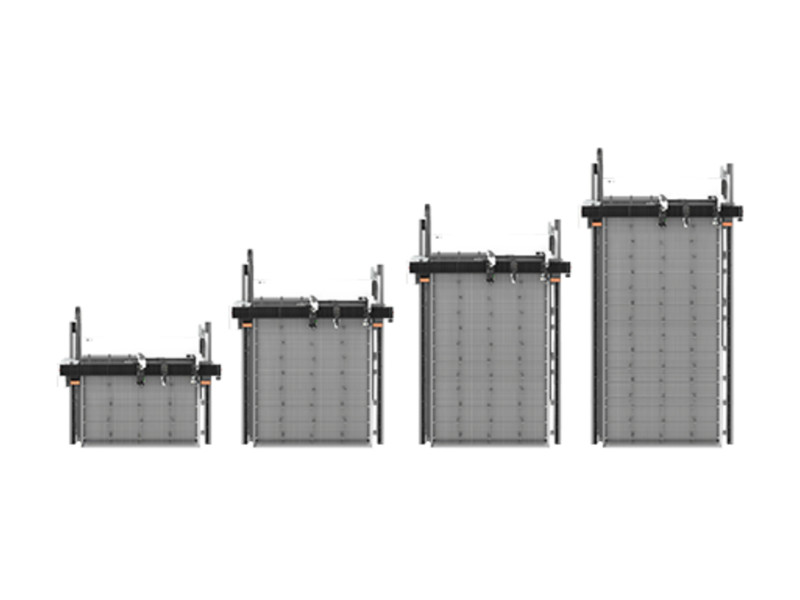

The M-Series was built using WARDJet’s modular design philosophy. This allows each machine to be tailored to your needs. The M-Series boasts the widest range of configurations in its class

Optimize Cutting Area

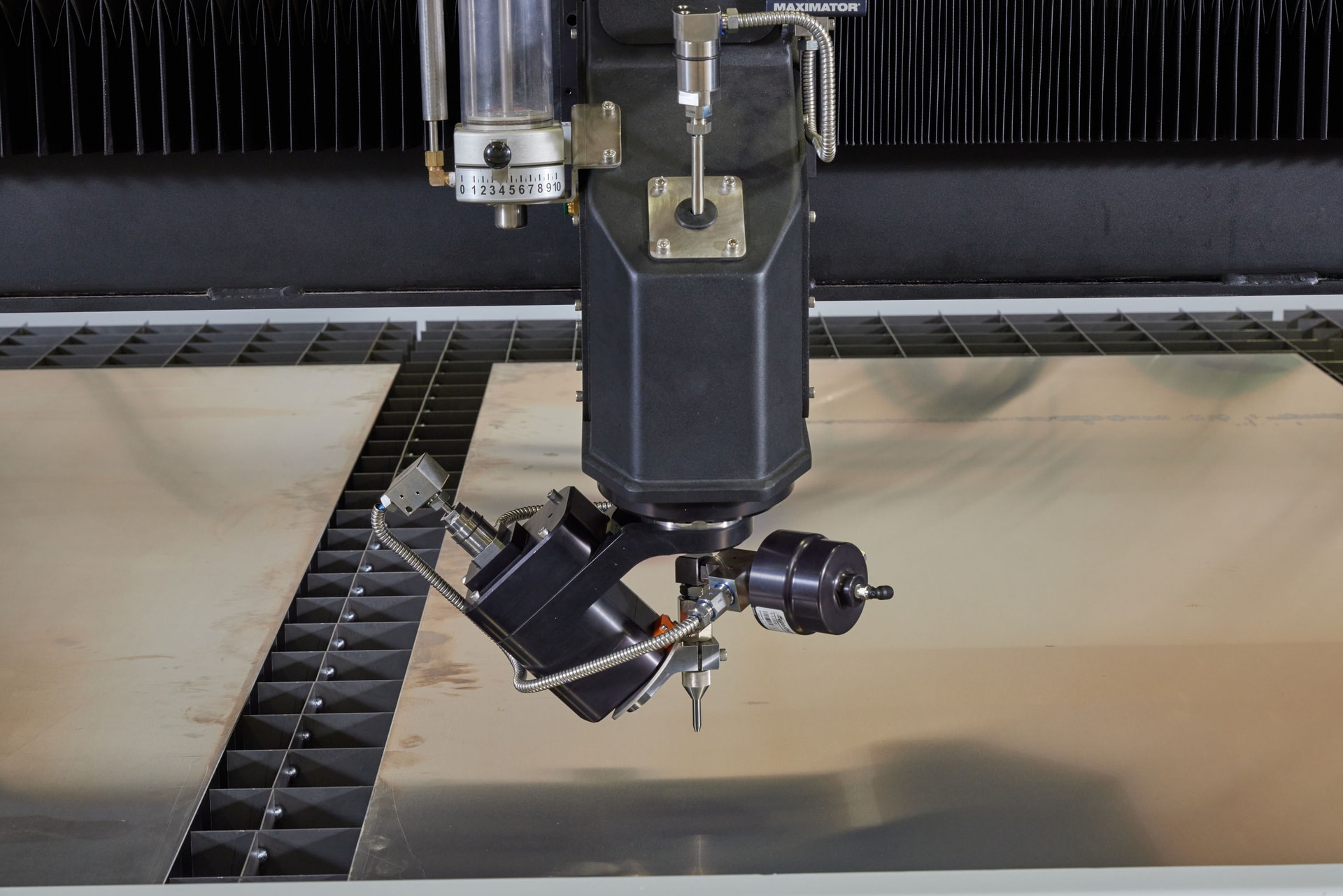

The M-Series uses decades of multiple head cutting to ensure maximum productivity. Park one of the heads to the side to utilize the full cutting area with one or two other heads. Program different head spacing to match each jobs’ requirement.

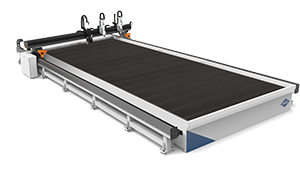

M-2520

Designed for industry-standard sheet sizes, the M-2520 maximizes access with a cutting area that is 8.2’ (2.5 m) in length x 6.6’ (2.0m) in width.

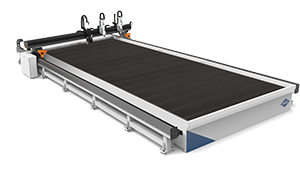

M-2530

Designed for industry-standard sheet sizes, the M-2530 maximizes access with a cutting area that is 8.2’ (2.5 m) in length x 9.8’ (3.0m) in width.

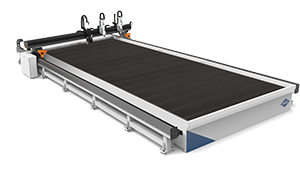

M-2540

Designed for industry-standard sheet sizes, the M-2540 maximizes access with a cutting area that is 8.2’ (2.5 m) in length x 13.1’ (4.0m) in width.

M-5020

Designed for industry-standard sheet sizes, the M-5020 maximizes access with a cutting area that is 16.4’ (5.0 m) in length and 6.6’ (2.0m) in width.

M-5030

Designed for industry-standard sheet sizes, the M-5030 maximizes access with a cutting area that is 16.4’ (5.0 m) in length and 9.8’ (3.0m) in width.

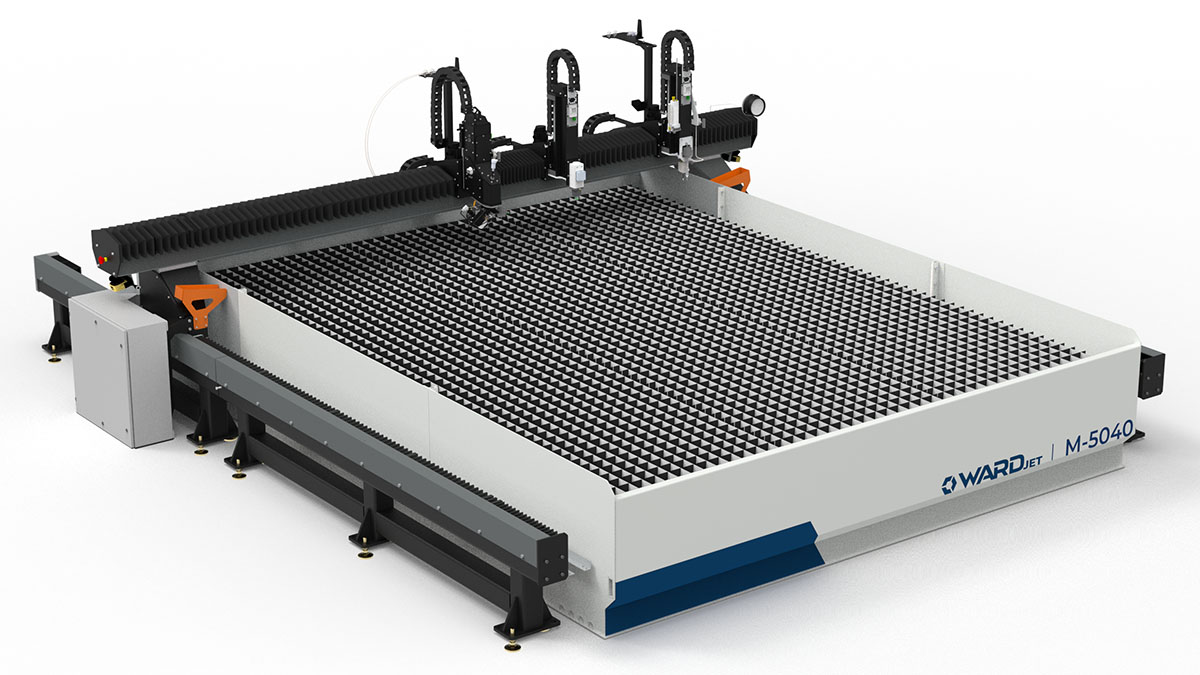

M-5040

Designed for industry-standard sheet sizes, the M-5040 maximizes access with a cutting area that is 16.4’ (5.0 m) in length and 13.1’ (4.0m) in width.

M-7520

Designed for industry-standard sheet sizes, the M-7520 maximizes access with a cutting area that is 24.6’ (7.5 m) in length and 6.6’ (2.0m) in width.

M-7530

Designed for industry-standard sheet sizes, the M-7530 maximizes access with a cutting area that is 24.6’ (7.5 m) in length and 9.8’ (3.0m) in width.

M-7540

Designed for industry-standard sheet sizes, the M-7540 maximizes access with a cutting area that is 24.6’ (7.5 m) in length and 13.1’ (4.0m) in width.

M-10020

Designed for industry-standard sheet sizes, the M-10020 maximizes access with a cutting area that is 32.8’ (10.0 m) in length and 6.6’ (2.0m) in width.

M-10030

Designed for industry-standard sheet sizes, the M-10030 maximizes access with a cutting area that is 32.8’ (10.0 m) in length and 9.8’ (3.0m) in width.

M-10040

Designed for industry-standard sheet sizes, the M-10040 maximizes access with a cutting area that is 32.8’ (10.0 m) in length and 13.1’ (4.0m) in width.

Features & Benefits

The M-Series mid-rail design gives you easy access to your material on all sides of the machine. This allows more of the machine bed to be used. It is the easiest access design on the market.

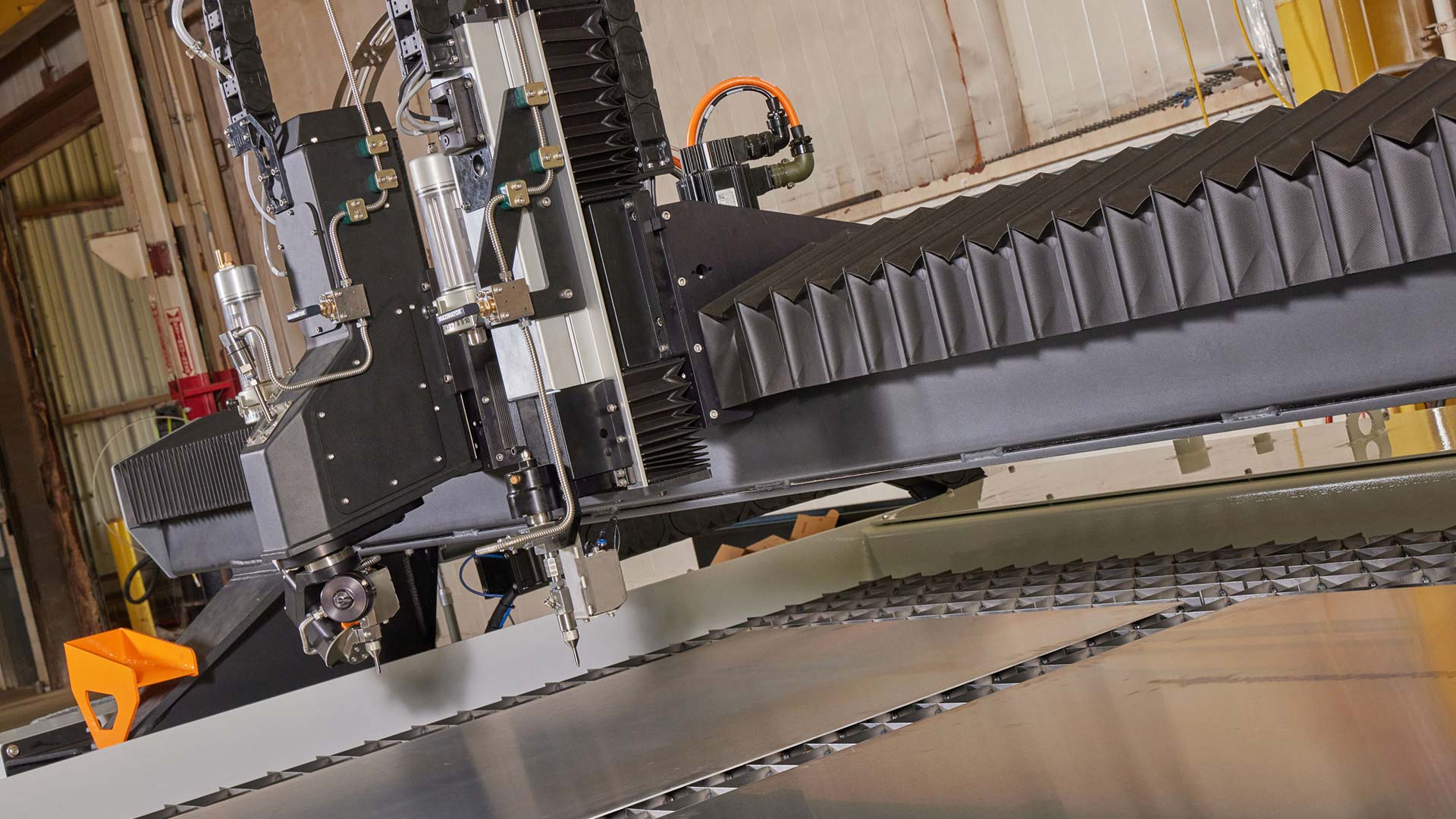

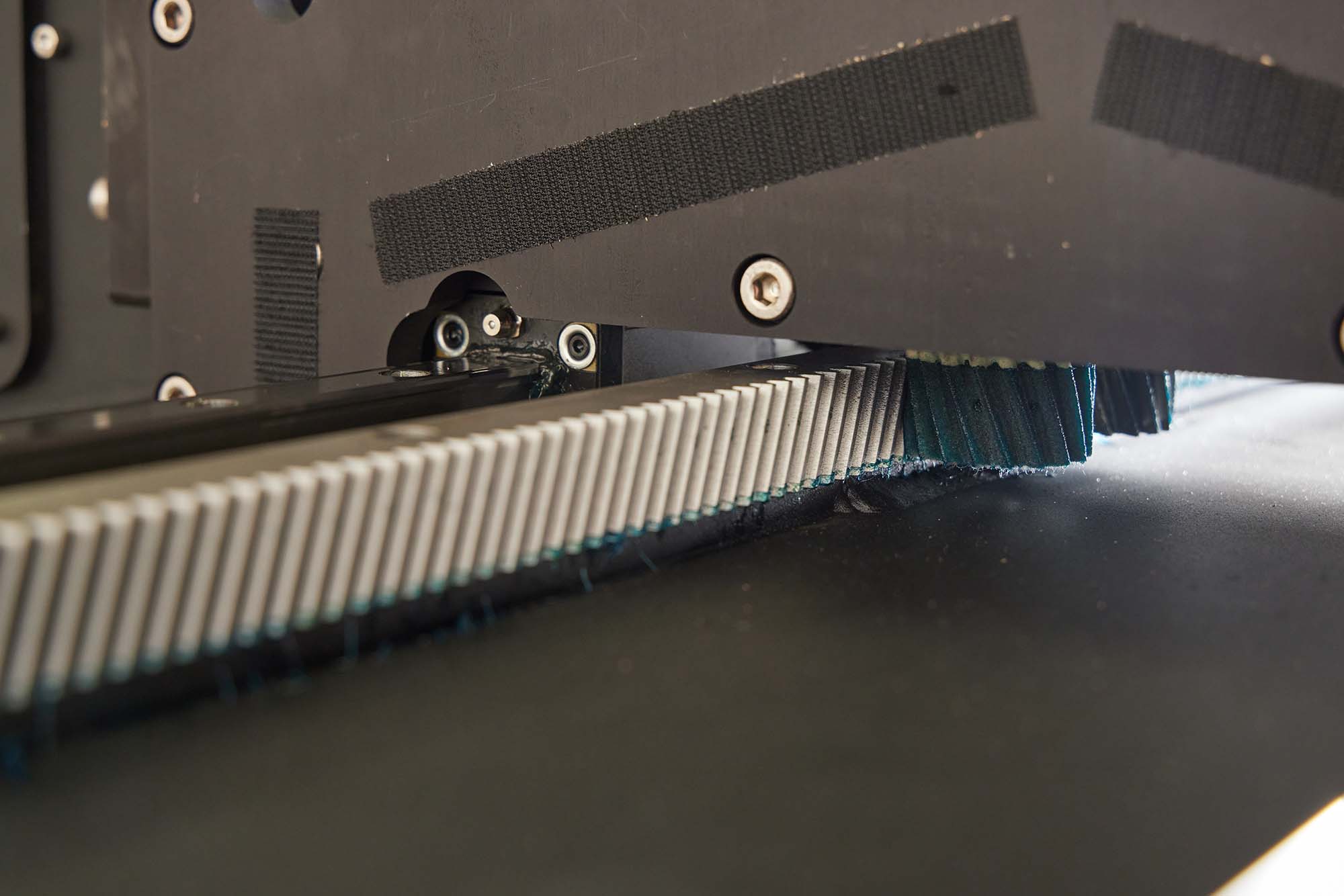

The M-Series uses premium drive systems to achieve traversing speeds of 1000 IPM. The precision helical rack and pinion ensures smooth motion and excellent cut quality.

The M-Series offers up to 3 head positions as standard using both 3-axis and 5-axis waterjet heads. If needed, we can customize our machine with more head positions. Our record is 16 heads on one gantry.

A Complete Package

More than just a waterjet, our 30+ years of service and commitment comes "bundled" with our waterjet cutting systems.

Upgradeability

Waterjet systems and accessories engineered to scale with your business

Unlimited Support

Stop waiting for a technician. Maximize your uptime with remote support.

Free Training

1-on-1 training with waterjet professionals for as long as you own your waterjet.

Online Resources

Most comprehensive training and support documentation in the industry.

Perform Better

We invite you to learn more about how our M-Series lineup can help you perform better within your industry.

Get in touch

Product Brochures

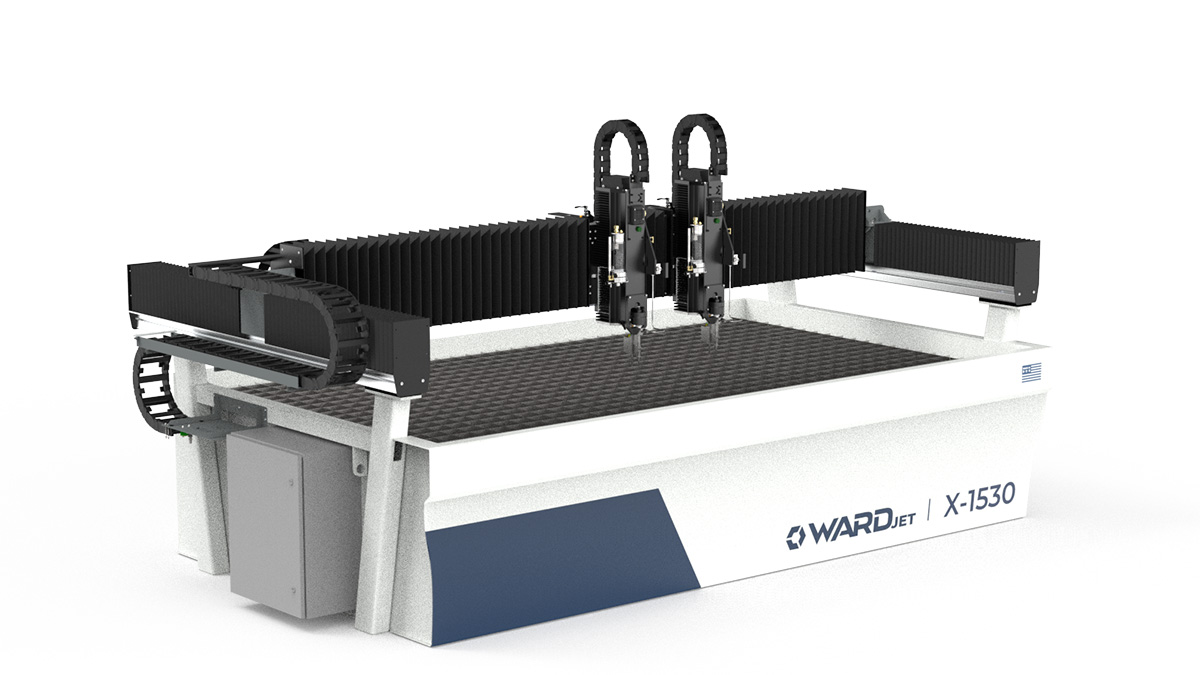

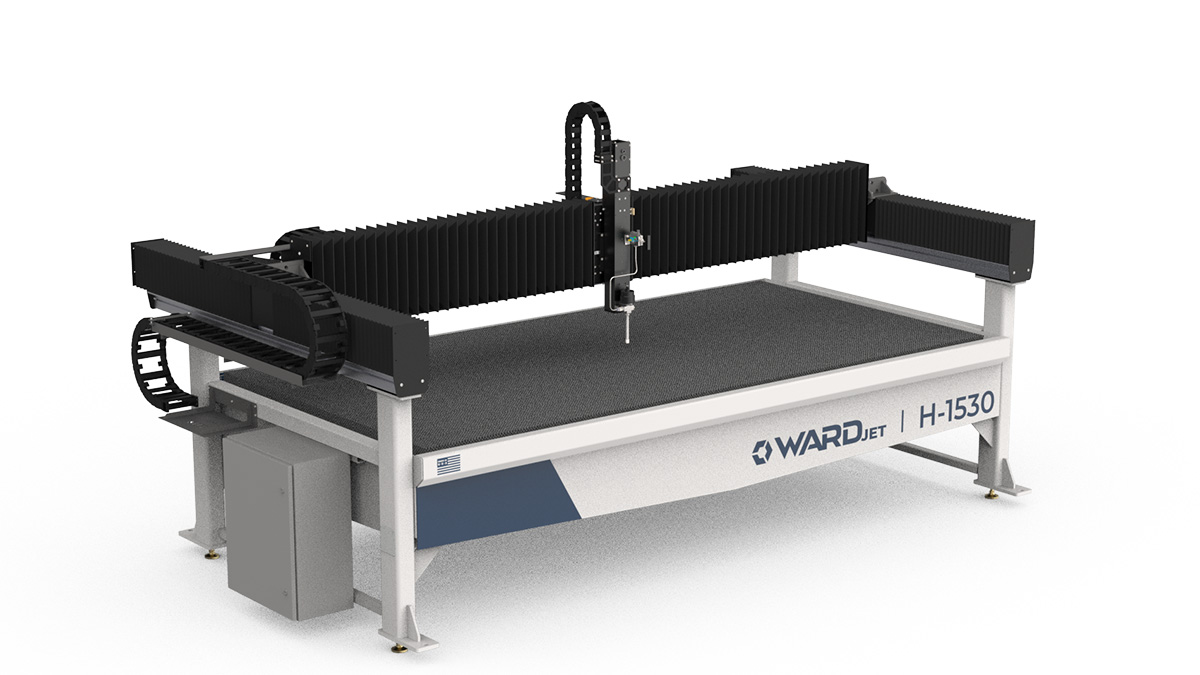

Get a copy of WARDJET's latest product brochure. Learn all about our extensive range of WARDJet CNC waterjets. Choose between our 6 big series - A-Series, X-Series, M-Series, H-Series, J-Series, and L-Series.